8

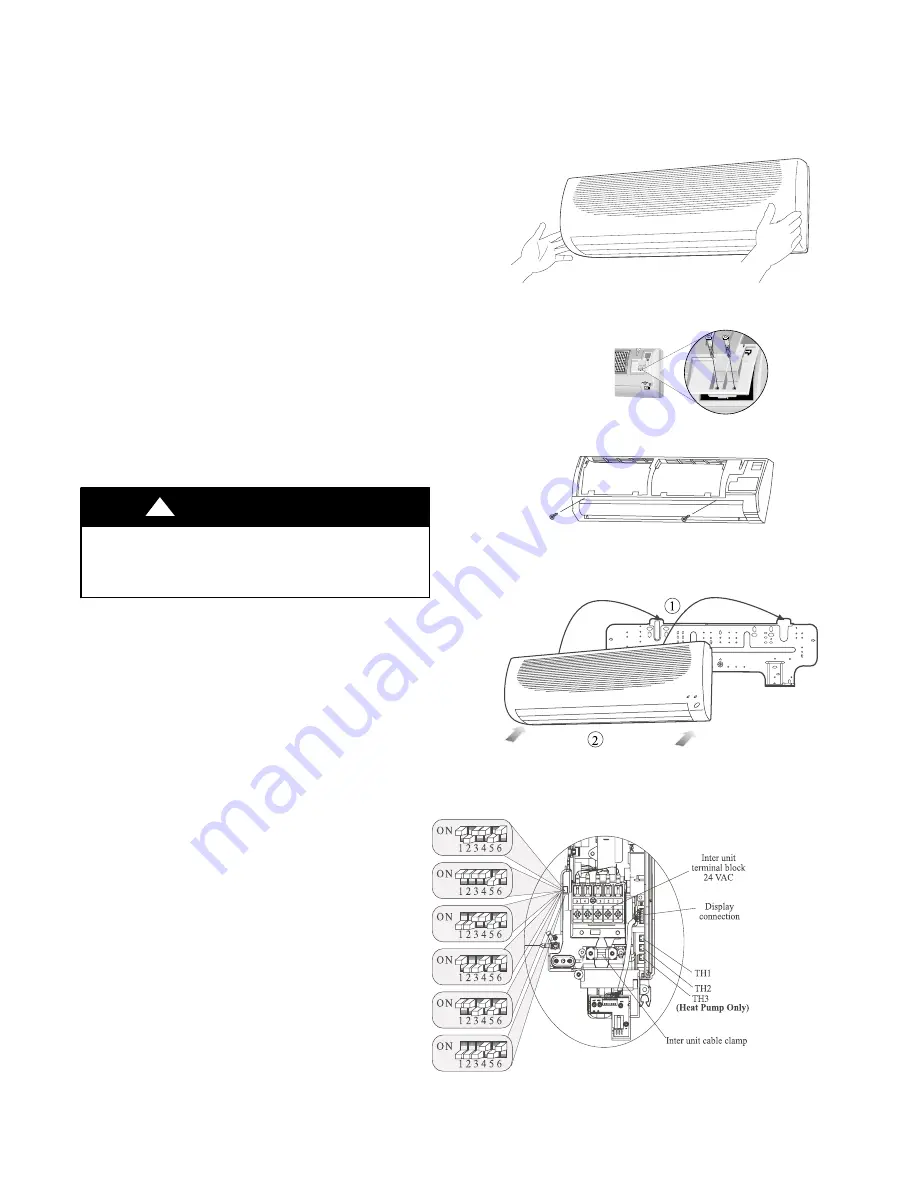

WIRE THE INDOOR UNIT

1. Strip the cables back 1/4 inch.

2. Remove the unit’s front panel by lifting the lower part and

pulling it gently outward and upward. See Fig. 6.

3. Remove the two screws from the control box cover and take

off the cover. See Fig. 7. Save the screws to reassemble.

NOTE

: In general wiring the indoor unit does not require the

removal of the grille frame but in case of need do as follows:

4. Remove the two screws from the air discharge opening.

Save the screws to reassemble. See Fig. 7A.

S

Pull downwards and outwards on the bottom of the grille

and gently raise the frame of the top of the unit.

S

Once all covers are off, mount the unit onto the wall mount-

ing bracket. See Fig. 8.

NOTE

: Leave covers off until after the Making Drainage

Connections section.

S

Route the interconnecting unit’s electric cable and the out-

door sensor cable towards the lower right hand corner of the

indoor unit.

S

Make sure that the wires are connected in accordance with

the wiring diagram on the inside of the unit front cover or

within this instruction manual.

S

Secure the control cables to the strain relief.

S

For heat pump systems only, connect the outdoor sensor

TH3 to its mating black terminal. See Fig. 9.

FIRE HAZARD

Failure to follow this warning could result in personal

injury, death and or property damage.

Make sure that all wires and screws are firmly fastened.

WARNING

!

MAKE DRAINAGE CONNECTIONS

1. Connect the unattached end of the drainage tube to the

drainage hose outlet.

2. Seal the drainage connection to prevent leakage.

3. Make sure there are no kinks, “U” bends or flattened sec-

tions in the tube.

4. Check that the drainage functions properly. Fill the pan

below the unit’s coil with water and observe that it freely

drains out.

5. Make sure the drainage hose is at the bottom side of the

wall through

−

hole (see Fig. 5).

REASSEMBLE

1. Connect the display connector to the display panel printed

circuit board.

2. Put the control box cover and grille frame back on using

the appropriate screws (Steps 3 and 4 of Wire the Indoor

Unit section). Put the grille insert back on.

Fig. 6

—

Remove Grille Insert

FILTER

IR

RECEIVER

POWER/AIRCOND

TIMER

FUSE

AUTO/OFF

FILTER RESET

SERVICE LED

POWER/AIRCOND

TIMER

FUSE

AUTO/OFF

FILTER RESET

SERVICE LED

AUTO/OFF

FILTER RESET

SERVICE LED

Fig. 7

—

Remove Control Cover

Sizes 30, 36

Fig. 7a

—

Remove the screws from the air discharge opening.

Mount the indoor unit on the mounting bracket

Gently push with the arrow direction

Fig. 8

—

Indoor Unit Mounting

HEAT PUMP

Model 24 DIP Switches location

(on the control box side)

HEAT PUMP

Model 30 DIP Switches location

(on the control box side)

COOLING ONLY

Model 30 DIP Switches location

(on the control box side)

COOLING ONLY

Model 36 DIP Switches location

(on the control box side)

COOLING ONLY

Model 24 DIP Switches location

(on the control box side)

HEAT PUMP

Model 36 DIP Switches location

(on the control box side)

Fig. 9

—

Outdoor Sensor Connection