484 01 3700 01

3

S

Place liquid filter dryer near ID unit to reduce the risk of

debris clogging the valve.

S

Make sure TXV bulb is securely fastened and wrapped in

the indentation on vapor line tube.

ENH4X Models:

These coils have a factory--installed hard--shutoff TXV

designed only for use with R--410A refrigerant. Use only

with outdoor units designed for R--410A.

NOTE

: All TXV’S have preset superheat settings and are

not field--adjustable.

Cabinet Sweating

If this unit is installed in a garage, attic, or other

unconditioned space, special attention needs to be given to

the potential of cabinet sweating. A 6 inch (152 mm) wide

piece of insulation should be wrapped around the coil

casing and supply duct connection point.

Condensate Management

With proper installation, these coils will manage the

condensate without blow--off into the duct work. The 60 size

coil requires the addition of a pan extension for both horizontal

left and horizontal right position, which is supplied with the

coils. See detailed instructions for more info. Also, refer to

Connect Condensate Drain Line section of this instruction.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage.

When installing over a finished ceiling and/or living area,

install a field--fabricated secondary condensate pan

under the entire unit.

CAUTION

!

HORIZONTAL--RIGHT AND

HORIZONTAL--LEFT WITH PAN EXTENSION

(5 Ton Size Only)

1. There are two separate pan extensions shipped with

the unit. For horizontal left installations, use the pan

attached to the left shipping bracket. For horizontal

right installations, use the pan attached to the right

shipping bracket. Be sure to use the correct pan

extension for the application. There should not be any

gaps between the plastic condensate pan and the

pan extension. All condensate should flow from the

pan extension to the plastic condensate pan and not

leak into the coil cabinet or duct.

NOTE

: Discard the pan not used along with both shipping

brackets.

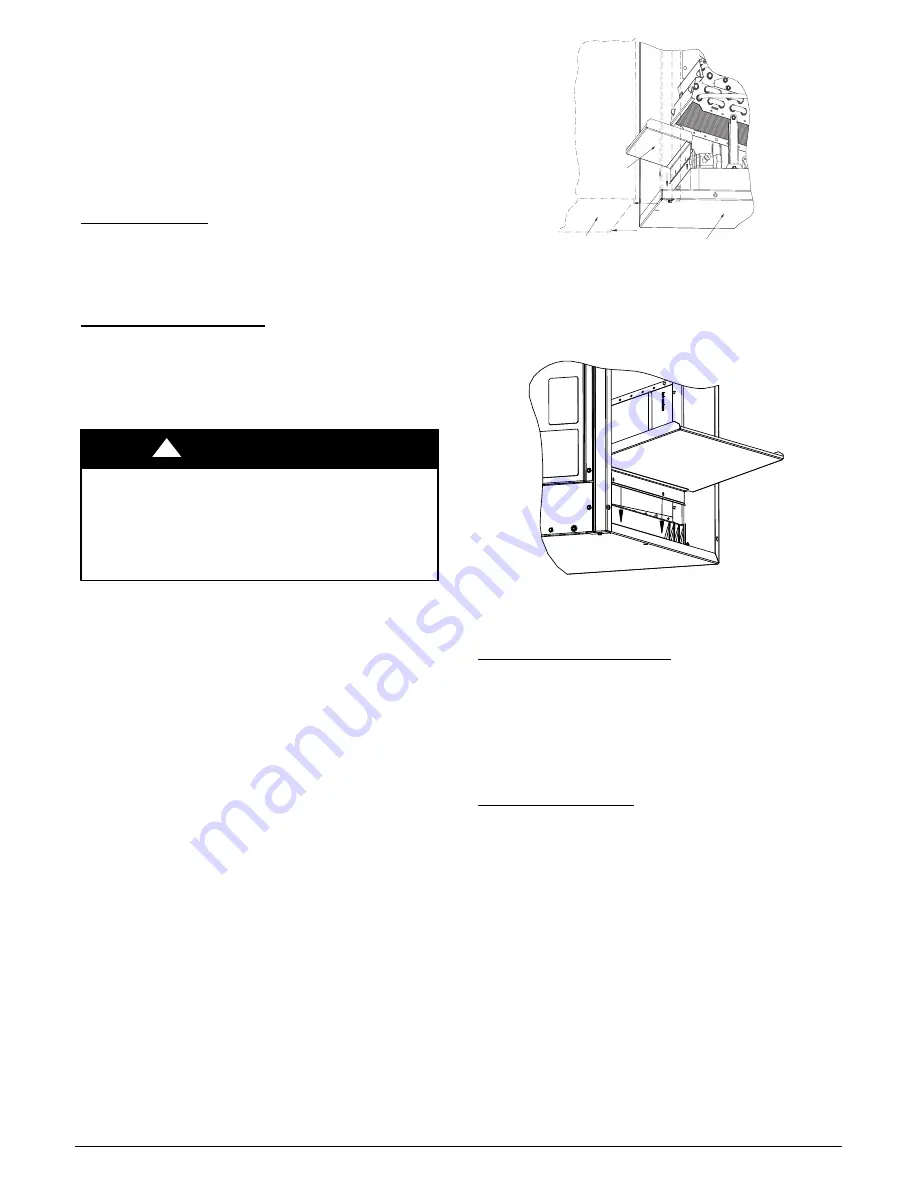

2. For horizontal--left installation, install pan extension

onto left end of horizontal--condensate pan. Pan

extension is slotted to fit onto condensate pan edge

and will extend into supply plenum. See Figure 4.

Supply

Plenum

Condensate Pan

Pan Extension

A06032

Figure 4 -- Horizontal--Left Installation of Pan Extension

3. For horizontal--right installation, install pan extension

onto right end of horizontal--condensate pan. Pan

extension is slotted to fit onto condensate pan edge

and will extend into supply plenum. See Figure 5.

A09084

Figure 5 -- Horizontal--Right Installation of Pan

Extension

Installation Configurations

These units can be installed on a work platform, secured to

roof trusses in the attic, suspended from hangers on floor

joists in the crawl space, or installed on blocks. See proper

section and figures for detailed installation instructions.

NOTE

: Pan extension is needed for both horizontal left and

right applications. DO NOT DISCARD.

FURNACE ATTACHMENT

Attach coil to furnace

The attachment plates (3) and filler plate (1) are packaged

together and placed in the coil carton. Remove these items,

verifying the number of pieces. Use the following procedure

to attach ENH4X horizontal coil to furnace.

NOTE

: Remove shipping brace from both ends of casing

prior to installation. Also remove corrugated shipping block

from inside the right end of casing prior to installation.

1. Three attachment plates are used to attach coil to

furnace. Application determines which end of the coil

will be attached to the furnace.

2. Use self--tapping screws to mount attachment plates

to coil casing. See Figure 6.