4

484 01 3700 01

A05419

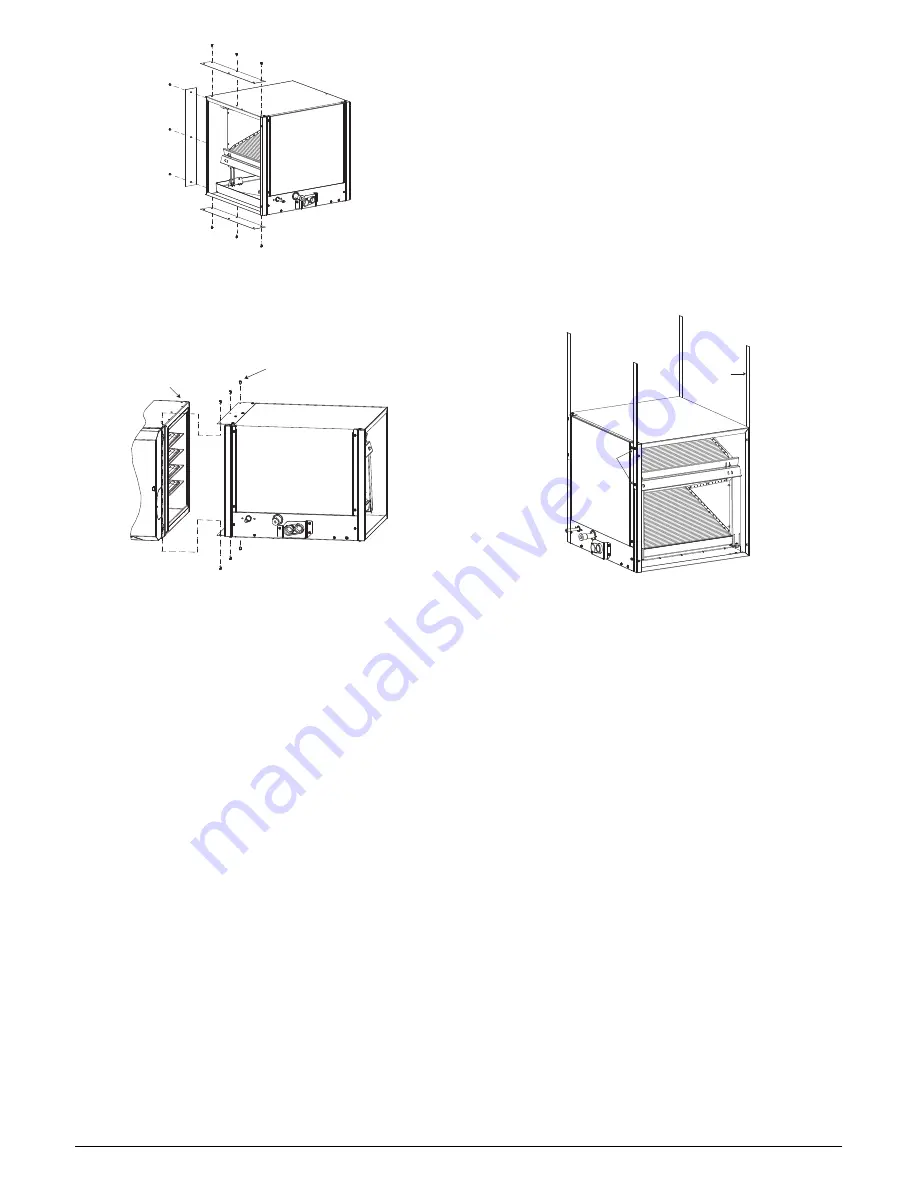

Figure 6 -- Mount Attachment Plates

3. Connect furnace snugly against coil casing.

4. Use self--tapping screws to attach furnace. See

Figure 7.

Self-Tapping Screws

Drill After Coil

Is Installed

A05420

Figure 7 -- Attach Coil to Furnace

5. Seal joint between coil casing and furnace to create

air--tight seal using locally--approved materials.

NOTE

: If the coil and furnace are different widths, refer to

Figure 2 and Figure 3.

HORIZONTAL ATTIC INSTALLATION

Construct work platform to support coil/furnace

combination

1. Construct work platform, using material in platform

that will support the weight of an installer or a service

person.

2. Place work platform in front of discharge end of

furnace.

3. Secure platform to building joists.

Install coil

To suspend ENH4X:

1. Cut metal plumbers strap to desired lengths.

2. Attach metal plumbers strap to four corners of coil

casing (see Figure 8).

3. Use a minimum of two screws per corner to attach

plumbers strap to casing.

4. Position and secure coil in front of furnace discharge

end.

5. Make sure coil is level for proper condensate

drainage.

6. Using appropriate fasteners for duct type, connect

supply--air duct to coil.

HORIZONTAL CRAWL SPACE INSTALLATION

As an alternate to horizontal attic installation, the ENH4X

horizontal coil can be installed in a crawl space by mounting

on suitable blocks, pads or by hanging from floor joists.

To suspend ENH4X:

1. Cut metal plumbers strap to desired lengths.

2. Attach metal plumbers strap to four corners of coil

casing. See Figure 8.

3. Use a minimum of two screws per corner to attach

metal plumbers strap to casing.

4. Position and secure coil in front of furnace discharge

end.

5. Make sure coil is level for proper condensate drainage.

6. Using appropriate fasteners from duct type, connect

supply--air duct to coil.

2 Screws for

Attachment

to Casing

Plumbers

Strap

A05421

Figure 8 -- ENH4X Suspension with Plumbers Strap