INSTALLATION INSTRUCTIONS

Gas Furnace: (F/G)9MVE

440 01 4400 03

33

Specifications subject to change without notice.

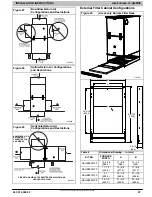

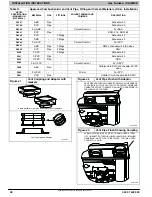

BX Cable Installation in Furnace J

−

Box

1. Install J

−

Box mounting bracket to inside of furnace

casing.

2. Route BX connector through 7/8

−

in. (22 mm) diameter

hole in casing and J

−

Box bracket.

3. Secure BX cable to J

−

Box bracket with connectors

approved for the type of cable used.

4. Connect field ground wire and factory ground wire to

green ground screw on J

−

Box mounting bracket as

shown in

5. Connect field power and neutral leads to furnace power

.

6. Attach furnace J

−

Box cover to mounting bracket with

screws supplied in loose parts bag. Do not pinch wires

between cover and bracket.

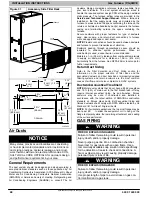

24

−

V Wiring

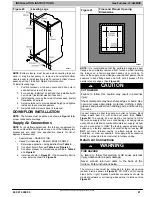

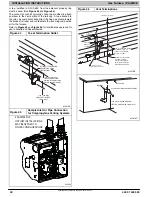

Make field 24

−

v connections at the 24

−

v terminal strip. (See

) Connect terminal Y/Y2 as shown in

for

proper cooling operation. Use only AWG No. 18, color

−

coded,

copper thermostat wire.

NOTE

: Use AWG No. 18 color-coded copper thermostat wire

for lengths up to 100 ft. (30.5 M). For wire lengths over 100 ft.,

use AWG No. 16 wire.

The 24

−

v circuit contains an automotive

−

type, 3

−

amp. fuse

located on the control. Any direct shorts during installation,

service, or maintenance could cause this fuse to blow. If fuse

replacement is required, use ONLY a 3

−

amp. fuse of identical

size. (See

)

See the Service and Technical Support manual for detailed

instructions on control wiring and setup.

Thermostats and Control Settings

Communicating, single

−

stage and two

−

stage thermostats may

all be used with this furnaces. Refer to typical thermostat wiring

diagrams and the Sequence of Operation section of the

Service and Technical Support manual for details on

configuring the furnace control board. Consult the thermostat

installation instructions for specific information about

configuring the thermostat.

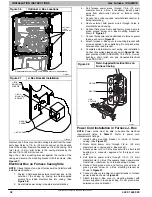

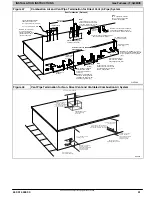

Accessories

(

See

)

1. Electronic Air Cleaner (EAC)

Connect an accessory Electronic Air Cleaner (if used)

using 1/4

−

in female quick connect terminals to the two

male 1/4

−

in quick

−

connect terminals on the control

board marked EAC

−

1 and EAC

−

2. The terminals are

rated for 115VAC, 1.0 amps maximum and are

energized during blower motor operation.

2. Humidifier (HUM)

The HUM terminal is a 24 VAC output, energized

when the blower is operating during a call for heat.

)

3. Communication Connector

This connection is used when the furnace is

controlled by an optional communicating wall control

instead of a standard thermostat. The communication

plug is supplied with the communicating wall control.

Refer to the instructions supplied with the

communicating wall control for complete details. (See

4. Outside Air Thermistor (OAT)

The OAT connection is used in conjunction with

communicating wall control. It is not required when the

furnace is controlled by a standard type thermostat.

Refer to the instructions supplied with the

communicating wall control for complete details. (See

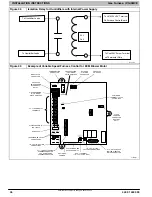

Alternate Power Supplies

This furnace is designed to operate on a utility generated

power which has a smooth sinusoidal waveform. If the furnace

is to be operated on a generator or other alternate power

supply, the alternate power supply must produce a smooth

sinusoidal waveform for compatibility with furnace electronics.

The alternate power supply must generate the same voltage,

phase, and frequency (Hz) as shown in

or on the

furnace rating plate.

Power from an alternate power supply that non-sinusoidal may

damage the furnace or cause erratic furnace operation.

Contact the alternate power supply manufacturer for

specifications and details.

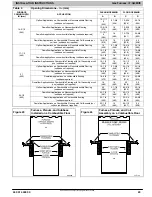

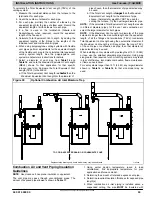

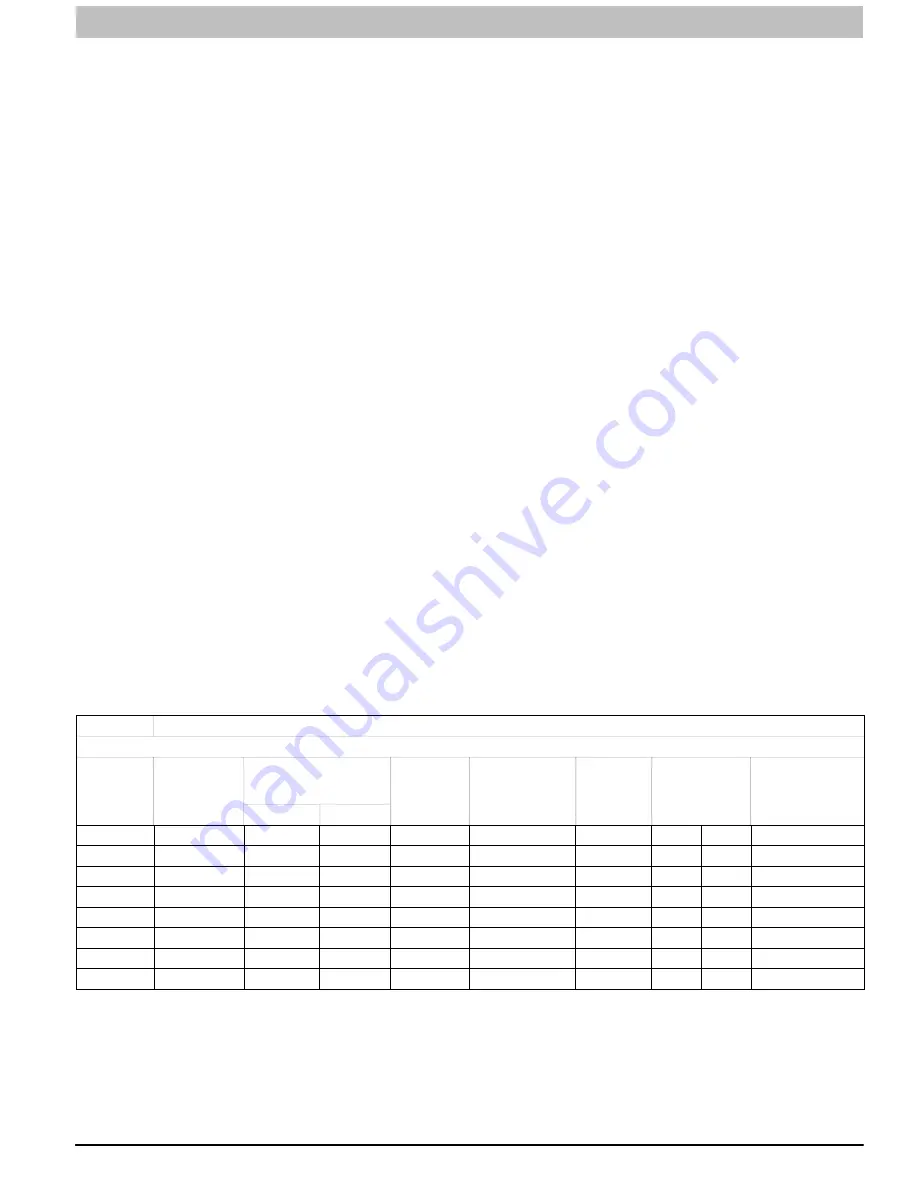

Table 11 Electrical Data

TWO

−

STAGE, VARIABLE SPEED FURNACES

UNIT SIZE

VOLTS

−

HERTZ

−

PHASE

OPERATING

VOLTAGE

RANGE*

MAXIMUM

UNIT

AMPS

UNIT

AMPACITY#

MINIMUM

WIRE

SIZE

AWG

MAXIMUM

WIRE

LENGTH

FT (M)

}

MAXIMUM

FUSE OR CKT

BKR

AMPS

{

Max*

Min*

0401410

115-60-1

127

104

7.5

10.3

14

36

(11.0)

15

0401712

115-60-1

127

104

7.5

10.2

14

36

(11.0)

15

0601412

115-60-1

127

104

7.6

10.3

14

36

(11.0)

15

0601714

115-60-1

127

104

9.2

12.4

14

29

(8.8)

15

0801716

115-60-1

127

104

9.2

12.4

14

29

(8.8)

15

0802120

115-60-1

127

104

11.7

15.5

12

37

(11.3)

20

1002120

115-60-1

127

104

11.8

15.6

12

36

(11.0)

20

1202422

115-60-1

127

104

11.8

15.6

12

36

(11.0)

20

* Permissible limits of the voltage range at which the unit operates satisfactorily.

# Unit ampacity = 125 percent of largest operating component’s full load amps plus 100 percent of all other potential operating components’ (EAC, humidifier, etc.) full load

amps.

Time

−

delay type is recommended.

Length shown is as measured one way along wire path between unit and service panel for maximum 2 percent voltage drop.