INSTALLATION INSTRUCTIONS

Gas Furnace: (F/G)9MVT, (F/G)9MXT, (F/G)9MXE

440 01 4001 05

43

Specifications subject to change without notice.

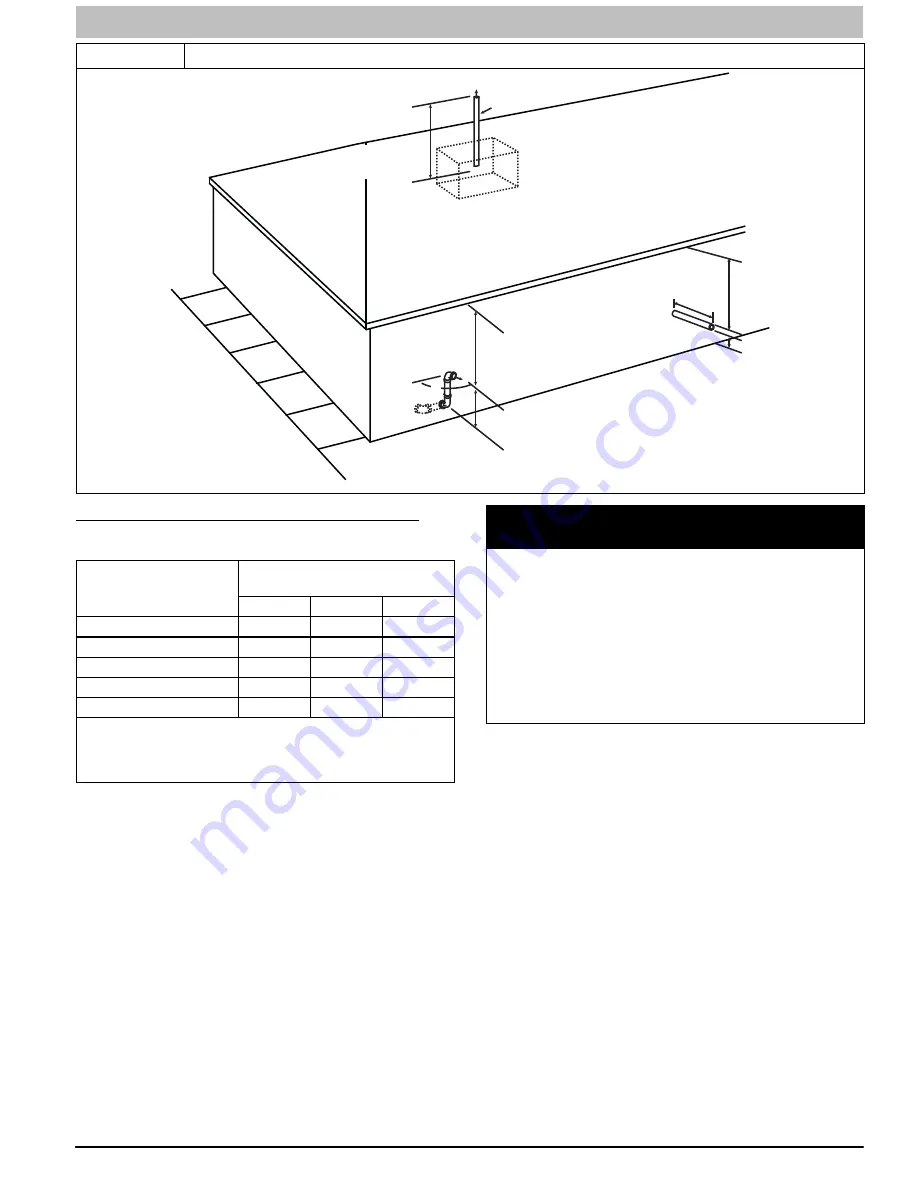

Figure 50

Vent Pipe Termination for Non

−

Direct Vent and Ventilated Combustion Air System

Abandoned masonry

used as raceway

(per code)

12 in. (305 mm) min. from

overhang or roof

Maintain 12 in. (305mm)

minimum clearance

above highest anticipated

snow level or grade

whichever is greater.

Side wall termination

with 2 elbows (preferred)

12 in. min. (305 mm)from

overhang or roof

Maintain 12 in. (305mm)

minimum clearance

above highest anticipated

snow level or grade

whichever is greater

6 in. (152mm) minimum clearance

between wall and end of vent pipe.

10 in. (254mm) maximum pipe length

Sidewall Termination

with Straight Pipe (preferred)

Roof Termination (Preferred)

Vent

Maintain 12 in

.

minimum clearance

above highest anticipated

snow level maximum of

24 in. (610mm) above roof

.

90

°

(305mm)

A05091

Size the Vent and Combustion Air Pipes

General

Vent or Combustion Air

Pipe Diameters

Approved 2

−

pipe

termination fittings

2

−

in.

3

−

in.

4

−

in.

1 1/2

−

in.

X

N/A

N/A

2

−

in.

X

N/A

N/A

2 1/2

−

in.

N/A

X

N/A

3

−

in.

N/A

X

N/A

4

−

in.

N/A

X

X

Note:

Optional accessory 2

−

pipe termination brackets are

sized for 2

−

in. and 3

−

in. Pipe. If a termination bracket is

required for a 4

−

in. termination, field fabricate the necessary

brackets and clamps.

Furnace combustion air and vent pipe connections are sized

for 2-in. (50 mm ND) PVC/ABS DWV pipe. The combustion air

and vent pipe connections also accommodate 60mm

polypropylene venting systems with outside diameters of

approximately 60 mm (2

−

3/8 inches). Any pipe diameter

change should be made outside furnace casing in vertical pipe.

Any change in diameter to the pipe must be made as close to

the furnace as reasonably possible.

The Maximum Vent Length for the vent pipe and combustion air

pipe (when used) equals the Maximum Equivalent Vent Length

(MEVL) in

Table 14

or

Table 16

, minus the number of fittings

multiplied by the deduction for each type of fitting used from

Table 15

.

NOTICE

OPTIONAL CONFIGURATION FOR COMBUSTION

AIR INLET PIPE

In applications where there is a risk of excessive mois-

ture entering the combustion air inlet pipe, a moisture

trap may be added to the inlet pipe to help prevent

moisture from entering the furnace from the combus-

tion air inlet pipe. See

Figure 51

.

When sizing venting systems, the equivalent length of

the optional moisture trap (15 feet/5 M) must be taken

into account

Optional Combustion Air Inlet

Moisture Trap

As an option to prevent moisture from trickling into the furnace

vestibule, a trap can be installed in the intake air pipe near the

furnace. Connecting a drain line to the trap is optional as trace

amounts of moisture will evaporate into the intake air stream. If

the combustion air inlet is located near a moisture exhaust

duct, or there are other concerns of excessive moisture being

drawn into the combustion air inlet, it is encouraged to connect

a drain line to the trap.

The trap can be constructed from a running tee of the same

diameter of the intake air pipe with EITHER a removable cap

attached to a 6-inch long pipe connected to the tee or the

External vent Trap Kit to help prevent contaminants from

entering the furnace. See

Figure 51

.

The External Vent Trap Kit accessory may be used as a trap for

the combustion air inlet pipe if a large amount of moisture must

be removed. The drain line may be connected to the same

drain as the furnace condensate and the evaporator coil

condensate line ONLY if the inlet air trap drain and the

evaporator coil drain empty into an open segment of pipe

above the drain, See

Figure 12

. When using the External Vent