INSTALLATION INSTRUCTIONS

Gas Furnace: N9MSE

440 01 4103 03

43

Specifications subject to change without notice.

3. For each pipe, multiply the number of elbows by the

equivalent length for the type of elbow used. Record the

equivalent length of all the elbows for each pipe.

4. If a Tee is used on the termination (Alberta and

Saskatchewan, when required), record the equivalent

length of the Tee used.

5. Calculate Total Equivalent Vent Length by adding the

equivalent lengths of the fittings to the lengths of the

individual vent and combustion air pipes.

6. When using polypropylene venting systems with flexible

vent pipes, perform adjustments for the equivalent length

of the flexible vent pipe to the calculated total equivalent

venting system length. See the polypropylene vent

system manufacturer’s instructions for details.

7. Select a diameter of vent pipe from

Table 14

and

Table 16

and note the Maximum Equivalent Vent Length

(MEVL) shown for that application for that specific

furnace input size. Compare the Total Equivalent Vent

Length (TEVL) to the MEVL:

a. If the Total Equivalent Vent Length is

shorter

than the

Maximum Equivalent Vent Length for the diameter of

pipe chosen, then that diameter of pipe selected may

be used.

b. If the Total Vent Length is

longer

than the Maximum

Equivalent Vent Length for the diameter of pipe

chosen, that diameter pipe MAY NOT be used for

venting the furnace. Try the next larger diameter pipe.

NOTE

: If the calculated Total Equivalent Vent Lengths results

in different diameter pipes for the vent and combustion air,

select the larger diameter for both pipes.

NOTE

: If the Maximum Vent Length for diameter of the pipe

selected is longer than the measured length and the equivalent

length of all the fittings and terminations (TEVL), recalculate

Total Equivalent Vent Length using the next smaller diameter. If

the Maximum Vent Length is still longer than the longer TEVL

of the vent pipe or combustion air pipe, then that diameter of

pipe selected may be used.

When installing vent systems with pipe lengths of 10 ft. (3.0 M)

or less, use the smallest allowable pipe diameter. Using pipe

size greater than required for short venting systems may result

in loss of efficiency, incomplete combustion, flame disturbance,

or flame sense lockout.

For vent systems longer than 10 ft. (3.0 M), any larger diameter

shown in

Table 14

or

Table 16

for that size model may be

used.

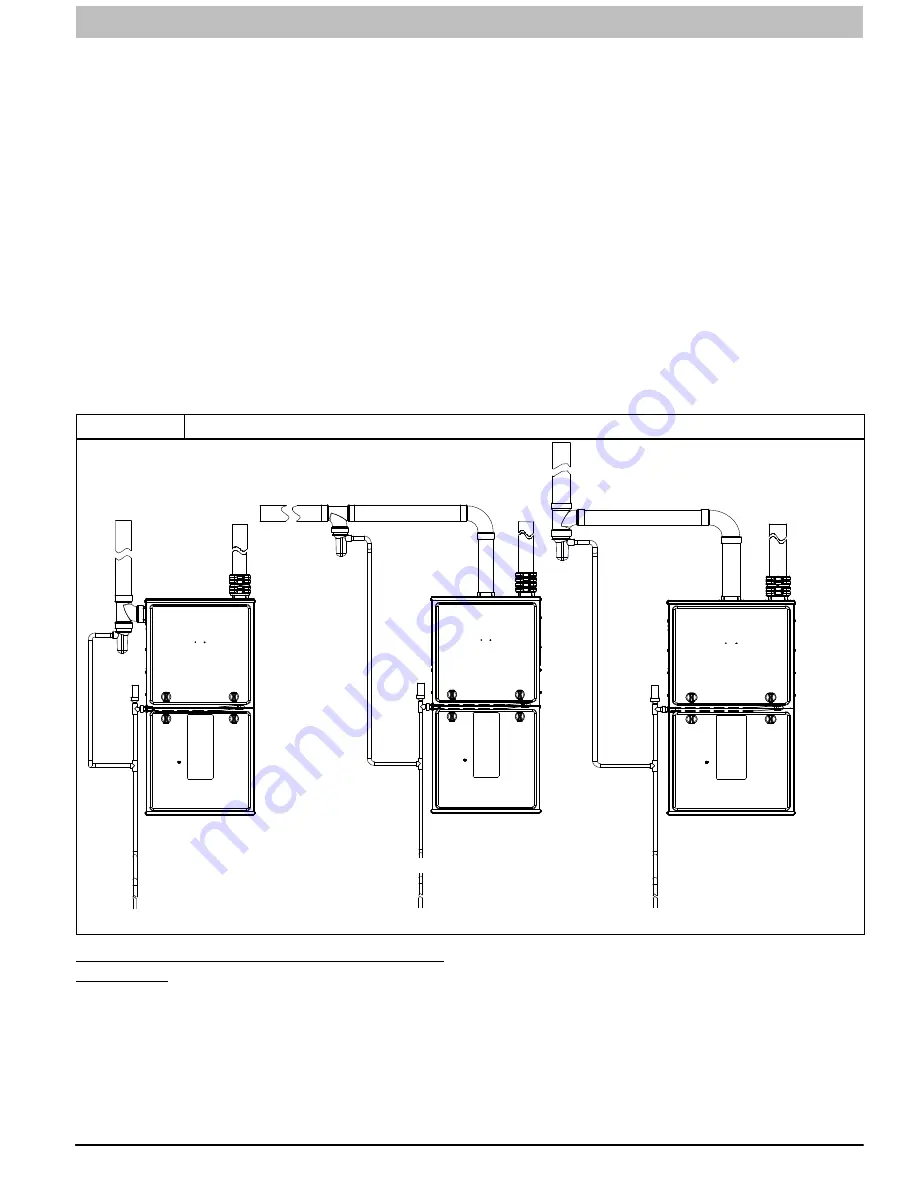

Figure 50

Optional Combustion Air Inlet Moisture Trap

Representative drawing only, some models may vary in appearance

TO

CODE

−

APPROVED

DRAIN

OR

CONDENSATE

PUMP

L12F028

Combustion Air and Vent Piping Insulation

Guidelines

NOTE

: Use closed cell, neoprene insulation or equivalent.

The vent pipe may pass through unconditioned areas. The

amount of exposed pipe allowed is shown in

Table 17

.

1. Using winter design temperature (used in load

calculations), find appropriate temperature for your

application and furnace model.

2. Determine the amount of total and exposed vent pipe.

3. Determine required insulation thickness for exposed pipe

length(s).

4. When combustion air inlet piping is installed above a

suspended ceiling, the pipe

MUST

be insulated with

moisture resistant insulation such as Armaflex or other

equivalent type of insulation.

5. Insulate combustion air inlet piping when run in warm,

humid spaces.

6. Install the insulation per the insulation manufacturer’s

installation instructions.

NOTE

: Pipe length (ft / M) specified for maximum pipe lengths

located in unconditioned spaces (See

Table 17

) cannot exceed

total allowable pipe length as calculated from

Table 14

through

Table 16

.