6

443 06 4002 00

Specifications subject to change without notice.

Figure 8

Label Locations

IMPORT

ANT

THIS BAG WIT

H

INSTR

UCTION

S

ENCLOS

ED M

UST

BE A

TTACH

ED T

O

FURN

ACE

ADHESIVE POUCH

REPRESENTATIVE DRAWING ONLY, SOME MODELS MAY VARY.

SECTION II: CONVERSION FROM NATURAL

GAS TO PROPANE

BURNER REMOVAL

1. Slide one

−

piece burner assembly out of slots on sides of

burner box.

2. Remove the flame sensor from the burner assembly.

3. Remove the natural gas orifices from the manifold and

discard.

Figure 9

Burner Assembly

FLAME SENSOR

(BELOW BURNER)

FLAME ROLL-OUT

SWITCH

FLAME ROLL-OUT

SWITCH

IGNITER

IGNITER

A11226

ORIFICE SELECTION/DERATE

!

WARNING

FIRE AND FURNACE DAMAGE HAZARD

Failure to follow this warning could result in personal injury,

death, property damage and/or unit damage.

DO NOT redrill orifices. Improper drilling (burrs, out

−

of

−

round

holes, etc.) can cause excessive burner noise and

misdirection of burner flames. This can result in flame

impingement of burners and heat exchangers causing

failures.

Figure 10

Burner Orifice

BURNER

ORIFICE

BURNER

ORIFICE

A96249

Refer to conversion kit rating plate 338298

−

101 to determine

main burner orifice size. (See

Figure 12

)

Furnace gas input rate on furnace rating plate is for installations

at altitudes up to 2000 ft. (610 M).

In the U.S.A., the input rating for altitudes above 2000 ft. (610

M) must be reduced by 2 percent for each 1000 ft. (305 M)

above sea level.

In Canada

,

the input rating must be derated by 5 percent for

altitudes of 2000 ft. to 4500 ft. (610 M to 1372 M) above sea

level.

The Conversion Kit Rating Plate accounts for high altitude

derate.

INSTALL ORIFICES

1. Install main burner orifices. Do not use Teflon tape.

Finger

−

tighten orifices at least one full turn to prevent

cross

−

threading, then tighten with wrench.

2. There are enough orifices in each kit for largest furnace.

Discard extra orifices.

NOTE

: DO NOT reinstall the manifold at this time.

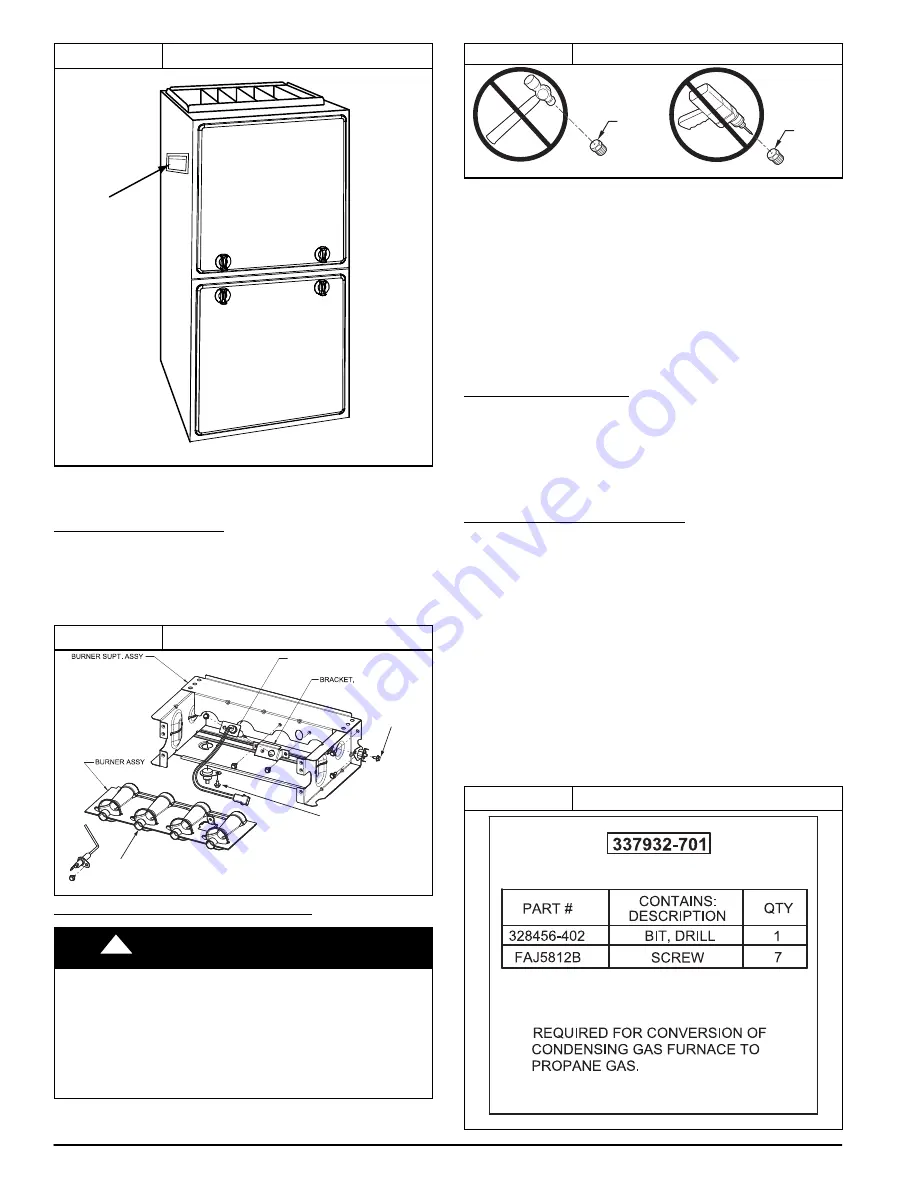

INSTALL MIXER SCREWS

NOTE

: There is a set of mixer screws. Use the parts in the bag

marked “REQUIRED FOR THE CONVERSION OF

CONDENSING GAS FURNACES TO PROPANE GAS”

1. See

Figure 11

to verify you have the correct set of mixer

screws.

2. Locate the dimple on each burner venturi tube.

3. If you cannot locate the dimple, refer to

Figure 13

for

location of the mixer screw.

4. Drill a 7/64

−

in (2.8 mm) hole (supplied in kit) in each

dimple.

5. Install a mixer screw in each drilled hole drilling as

straight as possible (i.e. in the center of the gas flow

stream as well as perpendicular to the gas flow stream).

6. The screw head should be flush with the top of the

burner venturi.

Figure 11

Gas Conversion Kit

A11294