14

513 01 3222 00

Specifications are subject to change without notice.

Units Without Factory--Installed

Non--Fused Disconnect —

When installing units, provide a disconnect switch per

NEC (National Electrical Code) of adequate size.

Disconnect sizing data is provided on the unit informative

plate. Locate on unit cabinet or within sight of the unit per

national or local codes. Do not cover unit informative

plate if mounting the disconnect on the unit cabinet.

All Units —

All field wiring must comply with NEC and all local

codes. Size wire based on MCA (Minimum Circuit Amps)

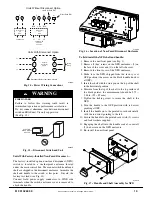

on the unit informative plate. See Fig. 14 and the unit

label diagram for power wiring connections to the unit

power terminal blocks and equipment ground. Maximum

wire size is #2 ga AWG per pole.

Provide a ground--fault and short--circuit over--current

protection device (fuse or breaker) per NEC Article 440

(or local codes). Refer to unit informative data plate for

MOCP (Maximum Over--current Protection) device size.

All field wiring must comply with the NEC and local

requirements.

All units except 208/230-v units are factory wired for the

voltage shown on the nameplate.

If the 208/230-v unit is

to be connected to a 208-v power supply, the control

transformer must be rewired by moving the black wire

with the

1

/

4

-in. female spade connector from the 230--v

connection and moving it to the 200-v

1

/

4

-in. male

terminal on the primary side of the transformer.

Refer to

unit label diagram for additional information. Field power

wires will be connected line--side pressure lugs on the

power terminal block or at factory--installed option

non--fused disconnect.

NOTE

: Check all factory and field electrical connections

for tightness.

Convenience Outlets —

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal

injury or death.

Units with convenience outlet circuits may use

multiple disconnects. Check convenience outlet for

power status before opening unit for service. Locate

its disconnect switch, if appropriate, and open it.

Lock--out and tag--out this switch, if necessary.

!

WARNING

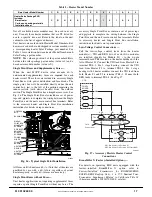

Convenience

Outlet

GFCI

Pwd-CO

Fuse

Switch

Pwd-CO

Transformer

Control Box

Access Panel

C08128

Fig. 18 -- Convenience Outlet Location

Non--powered Convenience Outlet:

These outlets require

the field installation of a general--purpose 125--volt 15--A

circuit powered from a source elsewhere in the building.

Observe national and local codes when selecting wire

size, fuse or breaker requirements and disconnect switch

size and location. Route 125--v power supply conductors

into the bottom of the utility box containing the duplex

receptacle.

Installing

Weatherproof

Cover:

A

weatherproof

while-in-use cover for the factory-installed convenience

outlets is now required by UL standards. This cover cannot

be factory-mounted due its depth; it must be installed at unit

installation. For shipment, the convenience outlet is covered

with a blank cover plate.

The weatherproof cover kit is shipped in the unit’s control

box. The kit includes the hinged cover, a backing plate and

gasket.

DISCONNECT

ALL

POWER

TO

UNIT

AND

CONVENIENCE OUTLET. LOCK--OUT AND TAG--OUT

ALL POWER.

Remove the blank cover plate at the convenience outlet;

discard the blank cover.

Loosen the two screws at the GFCI duplex outlet, until

approximately

1

/

2

-in (13 mm) under screw heads are

exposed. Press the gasket over the screw heads. Slip the

backing plate over the screw heads at the keyhole slots

and align with the gasket; tighten the two screws until

snug (do not over-tighten).

Mount the weatherproof cover to the backing plate as

shown in Fig. 19. Remove two slot fillers in the bottom of

the cover to permit service tool cords to exit the cover.

Check for full closing and latching.