16

513 01 3222 00

Specifications are subject to change without notice.

X

C

G

W2

R

C

W2

G

W1

O/B/Y2

Y2

W1

R

Y1

Y1

Ttypical

Thermostat

Corrections

T

H

E

R

M

O

S

T

A

T

(Note 1)

(Note 2)

(Note 3)

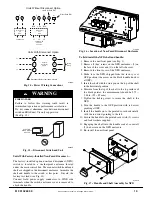

Note 1: Typical multi-function marking. Follow manufacturer’s configuration

instructions to select Y2.

Note 2: Y2 to Y2 connection required on single-stage cooling units when

integrated economizer function is desired

Note 3: W2 connection not required on units with single-stage heating.

Field Wiring

Central

Terminal

Board

C08575

Fig. 21 -- Low--Voltage Connections

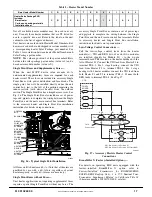

RACEWAY

HOLE IN END PANEL (HIDDEN)

C08027

Fig. 22 -- Field Control Wiring Raceway

NOTE

:

If thru--the--bottom connections accessory is

used, refer to the accessory installation instructions for

information on routing power and control wiring.

Heat Anticipator Settings —

Set heat anticipator settings at 0.14 amp for the first stage

and 0.14 amp for second--stage heating, when available.

Electric Heaters

RAS units may be equipped with field--installed accessory

electric heaters. The heaters are modular in design, with

heater frames holding open coil resistance wires strung

through ceramic insulators, line--break limit switches and

a control contactor. One or two heater modules may be

used in a unit.

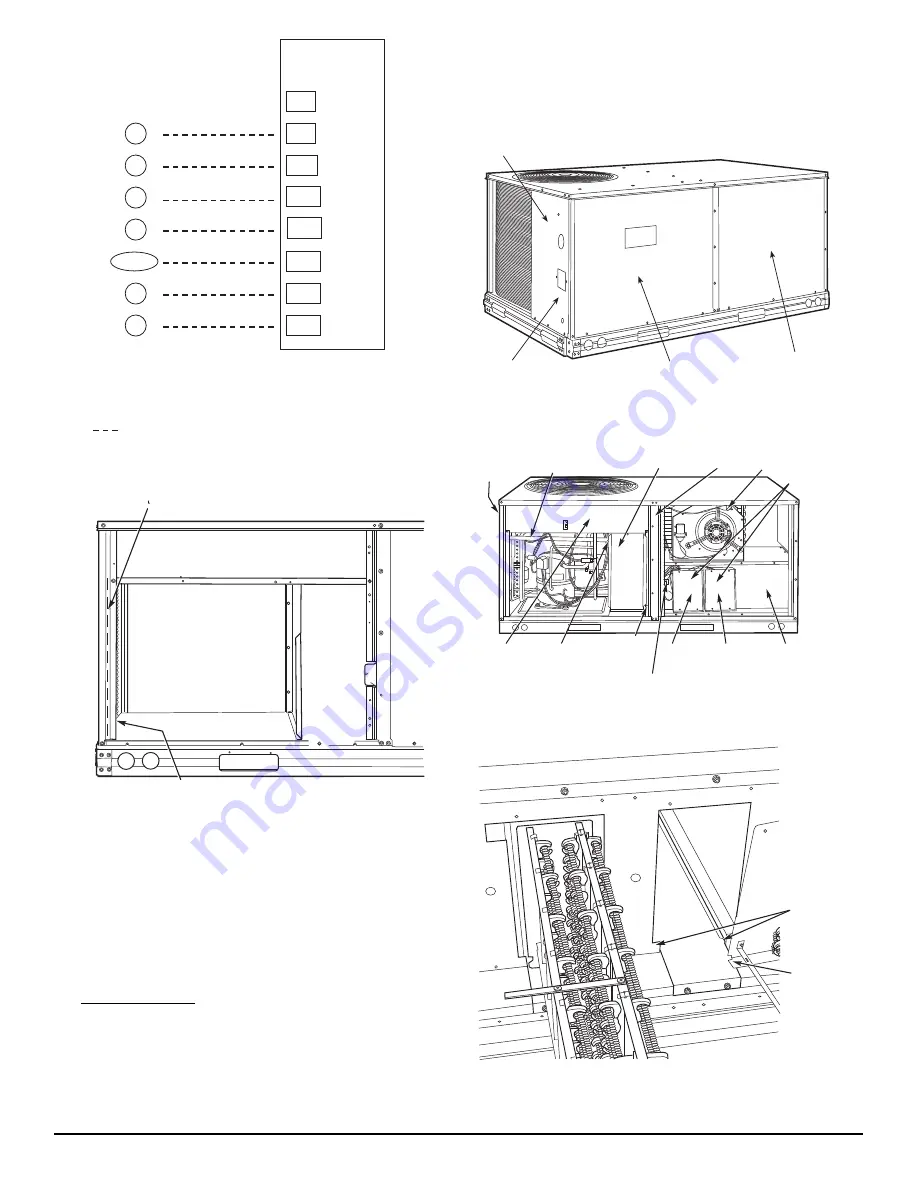

Heater modules are installed in the compartment below

the indoor (supply) fan outlet. Access is through the

indoor access panel. Heater modules slide into the

compartment on tracks along the bottom of the heater

opening. See Fig. 23, Fig. 24 and Fig. 25.

DISCONNECT MOUNTING

LOCATION

UNIT BLOCK-OFF

PANEL

OUTDOOR

ACCESS PANEL

INDOOR

ACCESS

PANEL

C08133

Fig. 23 -- Typical Access Panel Location (3--6 Ton)

DISCONNECT

MOUNTING

LOCATION

EMT OR RIGID CONDUIT

(FIELD-SUPPLIED)

SINGLE

POINT BOX

CENTER

POST

HEATER

COVERS

HEATER

MOUNTING

BRACKET

HEATER

MODULE

(LOCATION 2)

HEATER

MODULE

(LOCATION 1)

SINGLE POINT

BOX

MOUNTING

SCREW

BRACKET AND

CONDUIT

DRIP BOOT

MAIN

CONTROL

BOX

CONTROL WIRE TERMINAL BLOCK

MANUAL RESET

LIMIT SWITCH

C08134

Fig. 24 -- Typical Component Location

TRACK

FLANGE

C08135

Fig. 25 -- Typical Module Installation