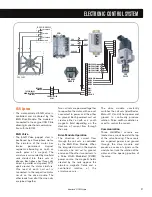

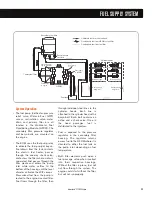

ELECTRONIC CONTROL SYSTEM

39

International

®

VT 275 V6 Engine

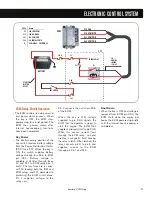

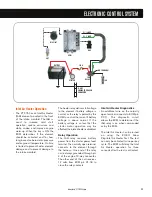

A/C Clutch Control

• The VT 275 ECM controls the A/C

clutch. The ECM receives an A/C

demand signal from the chassis,

and engages the A/C clutch if

engine conditions are correct. If

conditions are not right, clutch

action may be delayed. When the

ECM receives the A/C demand

signal, it considers engine run time

(to avoid stalling at start up) and

engine coolant temperature (to

avoid compressor operation when

liquid refrigerant may be present in

the compressor). In addition, the

ECM looks at transmission shift

action (to avoid clutch action during

a transmission shift), engine RPM

(to avoid clutch overspeed), and

APS percent (to avoid engagement

during full throttle acceleration).

A/C Demand

• The A/C demand signal originates

at the ECM as a reference voltage

on X3-10. The ECM supplies 5

volts to pin 10 and considers clutch

engagement when the voltage is

pulled low (shorted to ground) by

the A/C on/off switch in the dash-

located A/C Control Head.

The low-pressure switch (LPSW),

high-pressure switch (HPSW), and

the thermostat switch (T-STAT SW)

are in series in the A/C demand

circuit. If the compressor head

pressure rises above 350 psi, the

high-pressure switch opens and the

demand signal will be 5V. If

pressure on the low side of the

compressor goes below 7 psi, the

low-pressure switch will open and

the demand signal will be 5V.

The last switch is the thermostat

control in the A/C Control Head. If

the thermostat is positioned so that

in-cab temperature demands are

satisfied, the thermostat will open

and the demand signal will be 5V.

A/C Control

• If the A/C demand signal is pulled

low and the ECM determines that

the clutch can be engaged, the

ECM pulls the AC Control circuit

low at pin X3-22. When pin 22 is

low, a ground is provided for the

A/C Clutch Relay. The relay latches

and battery voltage is provided to

the A/C clutch through pin 5 of the

engine 12-way connector.

Switches

• The thermostatic switch (T-STAT

SW) monitors evaporator core

temperature to prevent freezing and

to regulate cab temperatures.

• The low pressure switch (LPSW)

prevents compressor damage in the

event of a refrigerant leak.

• The high pressure cutoff Switch

(HPSW) interrupts compressor

operation in the event of high

system pressures.

ECM

F34

F12

PDC

FUNCTION SELECTOR

SWITCH

HPSW

LPSW

T-STAT SW

ECT

TO

TRANS

CONTROLLER

X3-10 AC DEMAND

CAN1+

CAN 1(+)

CAN1-

CAN 1(-)

X3-22 AC CONTROL

TO IGN

SW

IGNITION

SWITCH

200A

MEGA

FUSE

TO BATTERY

POSITIVE

h

X1

X2

X3

X4

X1

X2

X3

X4

7

5

1

CA

2

CMP

APS

BATTERY

GRD

A/C

CLUTCH

A/C CLUTCH

DIODE

A/C CLUTCH

RELAY

3

5

1

2