26

LOWER TO

REST AGAINST

CARTON TOP

FLOATING

MECHANISM

LOCK HANDLE

Figure 11

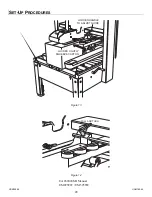

Width adjustment:

1.

Press the emergency stop button (figure 4) to shut-off machine.

2.

Use the width adjustment handle to spread the drive sections, enough to clear a

carton.

3.

Set a carton on the machine, as shown in figure 12.

4.

Use the width adjustment handle to move the drive sections closer together until

they lightly squeeze the carton, as shown in figure 12.

NOTE: The carton must only be slightly squeezed by the drive sections

UDM10008

UDM780-04

UA262024 SB Manual

UM095TW / UM595TW

S

ET

-U

P

P

ROCEDURES

Summary of Contents for IPG UA 262024 SB

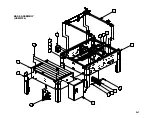

Page 40: ...4 7 2 3 5 10 9 11 12 13 15 14 8 6 19 17 16 18 1 BASE ASSEMBLY USM6104 A 1...

Page 42: ...4 19 13 5 10 12 18 3 8 9 1 6 22 7 2 17 16 15 14 20 BASE SUB ASSEMBLY UAM0352 A 3...

Page 46: ...A 7 LEG ASSEMBLY UAM0275 7 3 4 5 8 9 10 2 1 6 7 8 9 10...

Page 48: ...A 9 GATE ASSEMBLY USM6110 2 4 3 1 8 6 7 5...

Page 54: ...2 8 16 3 19 14 5 6 10 7 17 4 11 12 13 1 9 11 12 15 USM6100 A 15...

Page 56: ...2 10 4 3 5 9 13 12 17 8 7 14 15 16 1 11 14 15 18 6 USM6101 A 17...

Page 60: ...A 21 LOCKING MECANSM USM0391 6 1 5 7 2 3 4 8...

Page 62: ...A 23 COMPRESSION GUIDE USM6109 2 5 1 4 3 6 7...

Page 64: ...A 25 KNOB CW 5mm PIN UAM0288 4 5 3 2 1...

Page 75: ...A 36 ELECTRIC CONTROLS 2 1 4 8 3 6 5 7...

Page 79: ...A 40 AIR TO COLUMN ASSEMBLY 3 4 5 1 1 7 6 1 2...

Page 81: ...A 42 STOP START BOX UAM1084 STOP START BOX 5 4 7 1 10 8 2 9 3 6...

Page 87: ...A 48 SECOND E STOP INSTALLED OPTIONAL UM9003 1 3 4 7 5 6 2...

Page 89: ...A 50 SECOND E STOP BOX ASSEMBLY OPTIONAL USM8075 2 3 1 5 4...

Page 92: ...A 53 5 60 psi 3 5 PILOT 4mm TUBE AIR 8mm TUBE 3 KICKER GATE PNEUMATIC DIAGRAM...