10

2)

Choose a location where the transducer can be

mounted so that it will be level to the water’s surface and

will not be tilted to either side. Otherwise the transducer

will not scan from the surface ahead to directly beneath

the boat.

3)

The transducer must always remain submerged,

regardless of the speed of the boat and should not be

mounted where it could be damaged by underwater

obstacles or when loading on a trailer.

4)

DO NOT locate the transducer in the extreme

bow of the boat where it will be subject to intense

turbulence as the boat pounds through the water.

5)

DO NOT locate the transducer directly behind

any hull protrusion which will cause the water to be

turbulent when it reaches the transducer or which will

obstruct the transducer’s forward looking view. For

displacement-hull power and sail boats, the thru-hull

installation is usually required.

6)

DO NOT force the cable by pulling on it. This

may cause damage to the internal transducer wiring.

DANGER: DO NOT allow any solvents, i.e. gasoline,

acetone, to come in contact with the transducer or head

unit as this may dissolve the plastic material.

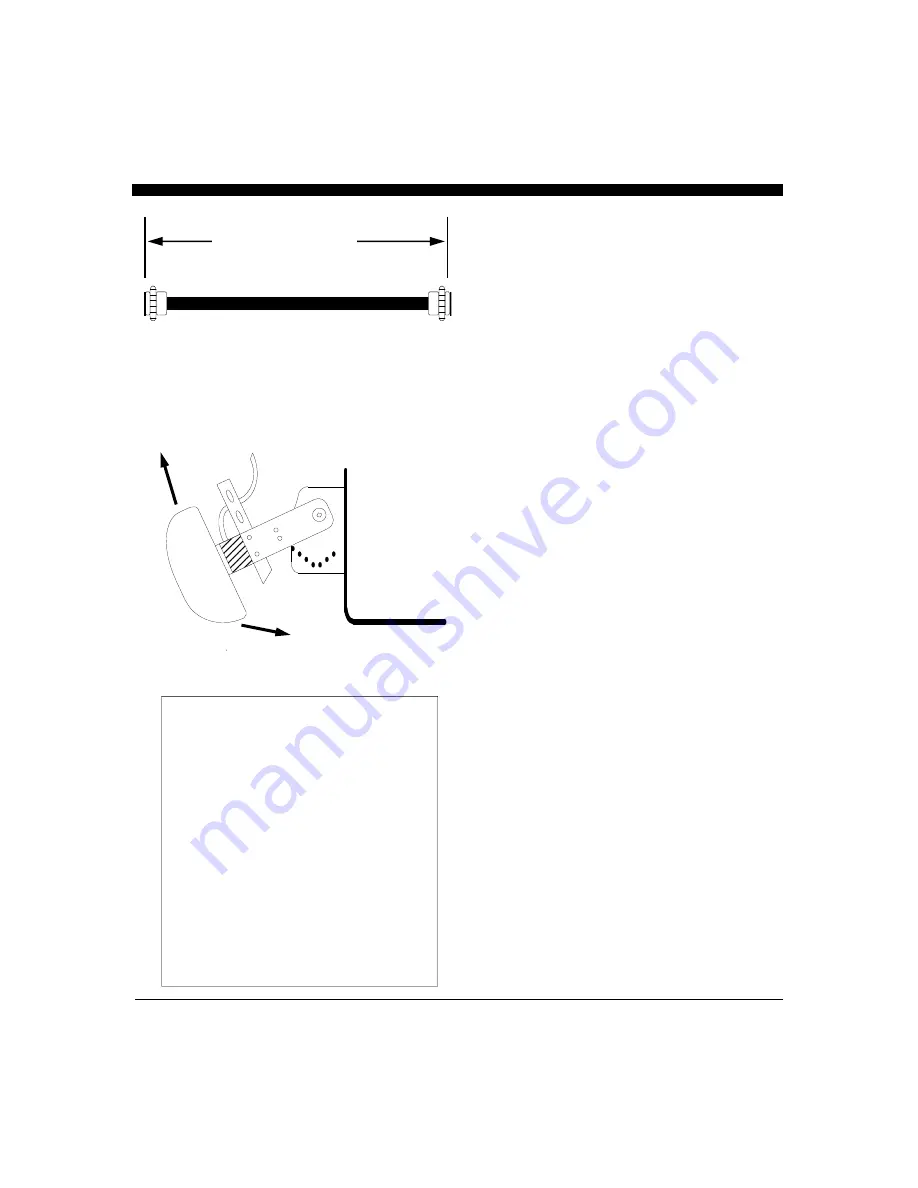

Transom Transducer Kick-Up Bracket

The transom transducer is attached to the boat with a

heavy-duty stainless steel kick-up bracket to provide

protection against impact

. When the transducer strikes an

object, or the water force exceeds the resistance of the

bracket, the transducer automatically kicks up and

becomes non-operational. The bracket does not

automatically reset at lower speeds. The transducer must

be manually returned to its operational position.

The transducer is designed to kick up at speeds between

35 and 40MPH (30-35 knots). We do not recommend

transom mount transducers on boats that regularly exceed

35MPH (30 knots).

Boats that exceed 40MPH

(35knots) cannot use transom mounted transducers,

but must use thru-hull transducers.

Special Note: The kick-up feature is designed as a safety

consideration to prevent the transducer from being

removed from the boat due to impact or excessive speed.

The kick-up bracket is not designed for repeated kick-up

30’ Extension Cable

9-pin

Male

9-pin

Female

Interphase Part #

04-0014-008

Suggested materials required for installation:

♦

Variable speed electric drill with a chuck

capacity of 10mm (3/8”) or larger.

♦

Hole saw or spade bit 19 mm (7/8”) for

transom hole to route cable and

connector

♦

Chamfer bit or 6 mm (1/4”) drill bit

♦

Drill bit No. 28 or 4 mm (9/64”)

♦

Drill bit 3 mm (7/64”)

♦

Marine bedding/sealing compound

Note: Will

not work at

speeds above

35 MPH

Transom Mount Bracket in Released Position

Summary of Contents for Outlook

Page 1: ...1 OPERATION MANUAL...

Page 36: ...36...