15

Installing the Thru-hull Transducer

1) Drill a 1/8” pilot hole from inside the hull to assure

access to tighten the housing nut and clearance for the

transducer cables. If there is any hull irregularity near the

mounting location, it may be desirable to drill from the

outside.

2) Use a 1-1/16” hole saw and drill the hole from the

outside of the hull. Sand or clean the area around the hole,

inside and outside to insure that the sealing compound will

adhere properly to the hull. Select a marine grade adhesive

sealant, such as 3M 5200, and use according to the

instructions.

3) Remove the bronze hex nut from the housing and cable.

4) Uncoil the transducer cable and thread it through the

hole into the inside of the hull.

DANGER: DO NOT apply

tension to the transducer cables as this may sever internal

connections.

5) Apply a 1/8” thick layer of sealant on the upper flat

surface of the transducer, bronze alignment pin and fairing

block (if used).

6) From the outside of the hull, push the housing into the

1” hole. Twist the housing slightly to squeeze out excess

sealant. Carefully confirm that the transducer is aligned so

that the round front end is pointed directly toward the front

of the boat.

7) Install and tighten the bronze hex nut (allow for swelling

in wooden hulls).

8) Remove excess sealant from the outside to assure

smooth water flow over the transducer.

DANGER: Wood hulls and fairing blocks will expand

after the boat is put back into the water, so it is important

that the transducer be only hand-tightened until the wood

fully expands. Otherwise the wood fairing block may

crack.

DANGER: Be sure to check for leaks when the boat is

placed in the water. Allow at least 24 hours after

installation for any leak to appear.

DANGER: If the boat is kept in saltwater it is

recommended that the transducer be coated with an anti-

fouling paint.

USE ONLY WATER BASED ANTI-

FOULING PAINT. DO NOT USE KETONE BASED

PAINTS. Ketone based anti-fouling paint will attack the

plastic materials used in the transducer.

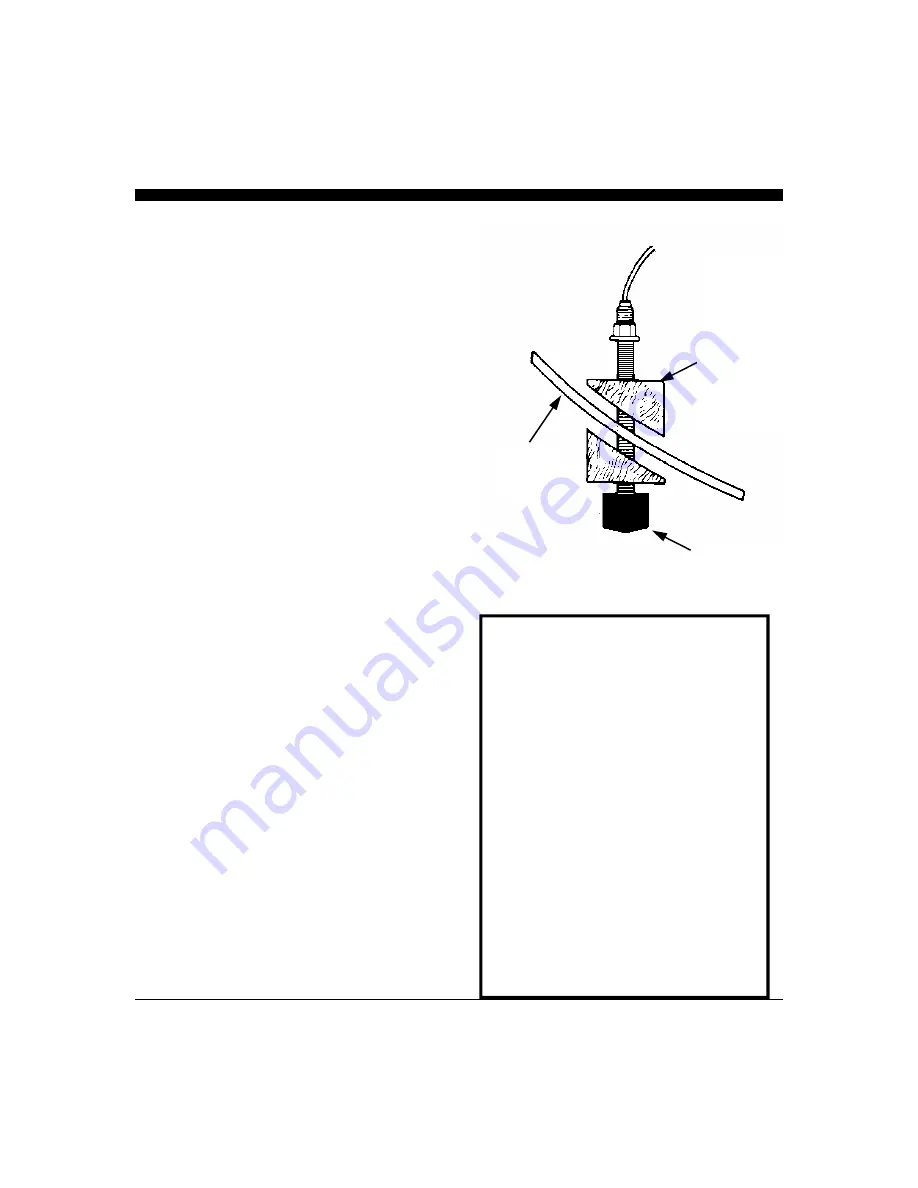

Transducer

Wood or

Plastic

Fairing

Block (Add

sealing

compound

between

faring block

& hull).

Boat’s

Hull

OPTIONAL SPEED/TEMPERATURE

TRANSDUCERS

INTERPHASE

DESCRIPTION

PART #

T1-0200-021

Transom mount S/T

transducer

T1-0200-027

Thru-hull mount S/T

transducer

04-0009-008

30’ S/T Extension Cable

Both the transom and thru-hull S/T transducers

are separately installed. The transom mount S/T

transducer can be used with the thru-hull depth

only transducer if desired. The 30’ S/T

transducer cable and the depth only transducer

cable both plug directly into the back of the

display unit.

To order, call your local

Interphase dealer, or

Interphase direct at (831)4 77-4944.

Summary of Contents for Outlook

Page 1: ...1 OPERATION MANUAL...

Page 36: ...36...