17

9 - PRECAUTIONS AGAINST FREEZING AND INSTRUCTIONS FOR STORAGE

If the machine is stored where temperatures fall below the freezing level, it is advisable to suck

antifreeze (similar to that used for automobiles) into the pump before storage. In any case keep

the machine in a warm r oom for a couple of minutes befor e use.

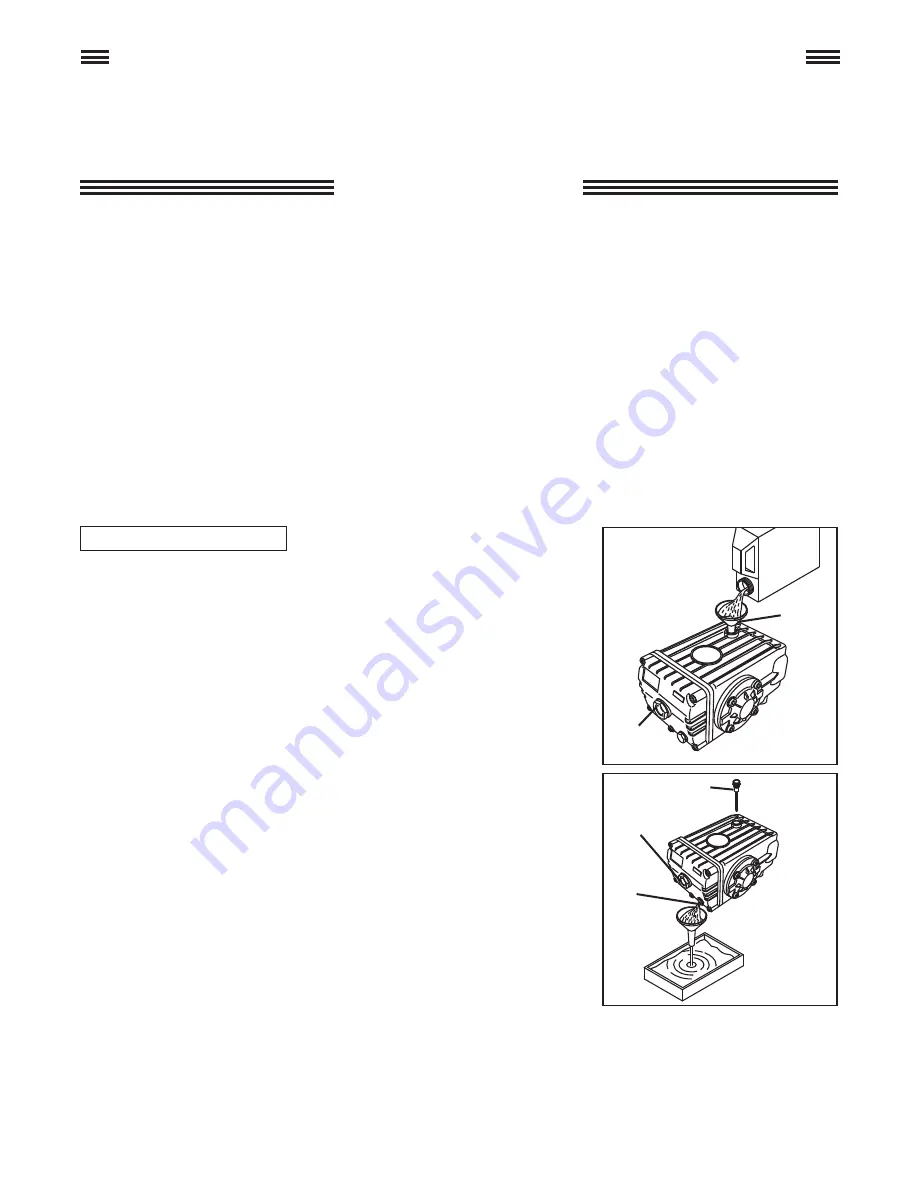

• Check oil level periodically thr ough the sight glass A or the

dipstick B.

• Oil must be changed after the first 50 hours of operation of

the machine. Subsequent oil changes must be carried out

every 300 hours of machine operation.

• In any case it is advisable to change the oil at least once a

year.

• Oil type: SAE 15W40 Mineral.

• Oil capacity: TX300 0.37 liter – TX500 1.1 liter .

• Unscrew the drain plug C placed under the pump and the oil

dipstick B.

• Let all the oil drip into a tank and bring it to an authorised

disposal center.

• Screw back the drain plug and fill the new oil fr om the top

bore D up to the half-way level of sight glass A.

A

B

A

c

D

10 - MAINTENANCE

10.1 - OIL CHANGE

• Maintenance and repairs should always be performed by trained and authorised personnel.

• Before carrying out any cleaning, maintenance and/or parts r eplacement,

disconnect the

machine from the power mains

, removing the plug from the power outlet.

• Proper maintenance favours a longer duration of operation and impr oved performance.

• Periodically check the conditions of the washer, pressurised parts (pipe, fittings, lance) and

the electrical cable (see "General war nings for use").

Check for any water or oil leaks and/or malfunctions.

If necessary, replace affected parts.

The list of specific machine components and cir cuit diagrams are contained in the booklet

"SPARE PARTS NOMENCLATURE".

Contact Interpump Group customer service in the event of any doubts.