15

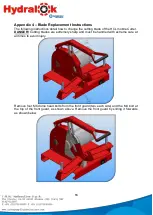

Remove the M6 clamp plate bolts (x2) by locating a bar or hex key into the torsion restraint

holes in the blade boss, shown above. Once both bolts have been removed the clamp

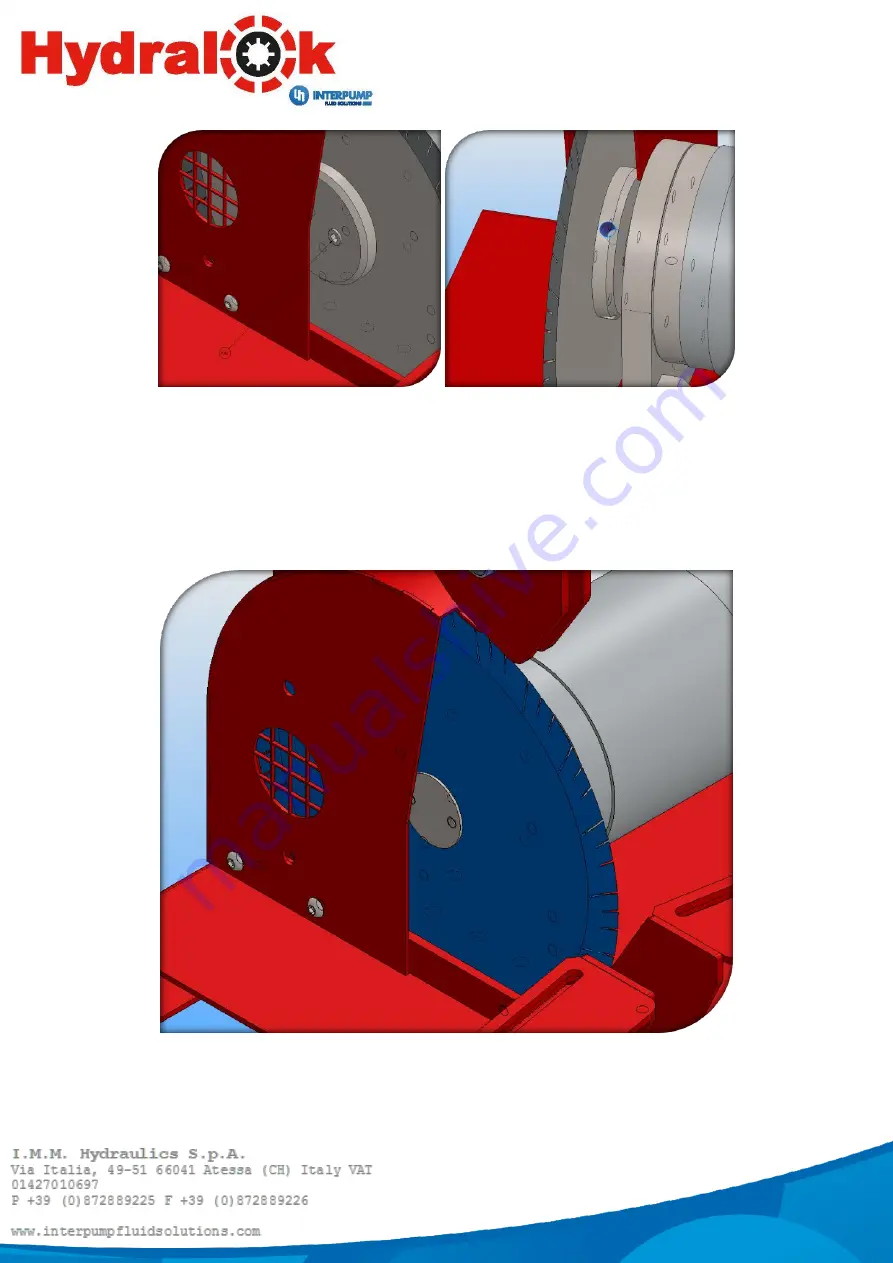

plate can be removed and the blade can be carefully removed and replaced as shown

below ensuring that the teeth are pointing in the correct direction. Once the new blade is

installed these steps can be repeated in reverse to reinstate all of the machine

components. Ensure that thread locker is applied to the blade clamp bolts on reassembly

to prevent loosening over time.