6

TECHNICAL / DIMENSIONAL DATA

TECHNICAL/DIMENSIONAL DATA

HCL MOBILE

Capacity

3/16” -1 1/2”

R1AT/1SN/R2AT/2SN (2 wire)

3/16” -1 1/4” R9R/4SP (4 wire)

Motor [Kw]

1.8

Dimensions [mm]

Ø 250x3

Gross Weight [kg]

29

Volts [V]

12 / 24 VDC

Noise level

< 75 dB

HANDLING/TRANSPORT

The machine will normally be shipped bolted to a wooden pallet. The bolts should be

removed and the machine lifted onto the work place using suitable lifting equipment.

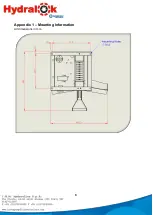

INSTALLATION

The machine must be fixed to a firm, and level work surface, bolted down by a minimum of

twobolts located in opposing corners of the machine. Mounting information can be found in

Appendix 1

– Mounting Information.

Connections should be made to an appropriate 12v / 24v DC electrical supply by a

qualified electrician. Standard wire colour coding is applied where the

RED

wire terminal

must be connected to the positive/live supply terminal, and the

BLACK

wire must be

connected to the negative/neutral supply terminal. For electrical schematic see Appendix 2

– Wiring Schematic.

A separate 160

‐

180 amp battery coupled to a split charger is recommended. Alternatively

a 110

‐

120 amp battery can be used for light duty. To ensure a maximum 12 volt DC

supply is delivered to the machine, a minimum cable size of 25 mm square with a

maximum length of four meters can be fitted. A suitable isolator and overload protection

device should be fitted to the voltage supply line.

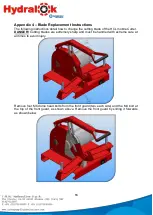

Prior to operation, ensure that the blade is free to rotate without fouling on any of the

guards and that the guards are operating correctly and covering the cutting blade

completely.