7

PRELIMINARY CHECKS

Place the machine on a stable surface. Where applicable, ensure that the power supply

line is fitted with a differential safety breaker and overload cutout.

LIGHTING

The equipment does not have its own lighting and so it must be used in a suitably

illuminated area.

ROUTINE MAINTENANCE

Regular inspection of the guards must be carried out and under no circumstances must

the machine be operated with damaged or inactive guarding.

The cutting blade should be regularly inspected for damage and lose of cutting

performance. A damaged blade must NOT be used. Where the machine is in constant use

a daily check is recommended. If the blade is damaged or the cutting performance is

reduced the blade will need replacing (or regrinding).

MACHINE

DESCRIPTION

A bench mounted, electrically powered rotating circular, toothed knife. Cutting operation is

powered by hand. The machine is intended to be used for cutting steel wire reinforced

rubber hydraulic hose or similar.

OPERATING

INSTRUCTIONS

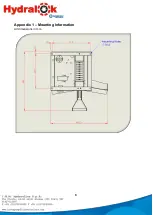

To move the hose support pillars (object 4 of Appendix 3

– Machine Diagram), unscrew

the clamping handle 1

‐

2 rotations, slide the pillar to position, and re

‐

tighten the clamping

handle. Set the hose support pillars an equal distance apart from the blade, so that when

the handle (1) is pushed down the hose is put under reasonable bending strain to relieve

pressure on the sides of the blade during the cutting operation.

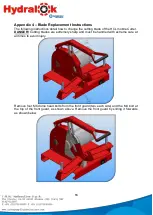

Place the hose into the cutting jaws (6) so that the hose bends out towards the user and is

supported by the hose support pillars (4). Ensure that the cutting mark is directly between

the hose cutting jaws (6). Switch on the machine using the green portion of the control

button (3) and push the handle downwards

SLOWLY

.

Allow the blade to cut through the hose at a controlled rate without excessive slowing of

the blade. When the hose is cut, allow the handle to return to a fully up position where the

blade is fully covered and switch off the machine using the red portion of the control button

(3).