8

MAINTENANCE AND SERVICE

Regular inspection and routine cleaning of the machine, focussing especially on the guards

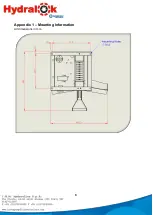

(Appendix 3

‐

7 & 8). Under no circumstances should the machine be used if the guards have been

damaged or removed.

The cutting blade should be inspected regularly for signs of wear or damage.

DANGER!

The

machine must not be run if the blade shows signs of damage or stress cracking as projectiles may

cause serious injury as the blade rotates at very high speeds.

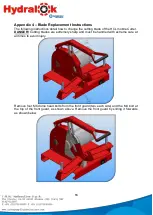

To replace the blade, follow the instructions in Appendix 4

– Blade Replacement Instructions.

NOISE EMISSION

Readings taken of this model of machine, mounted on a wooden work bench in the working

position at a distance of 1.1m above floor level was 75dB(A).

Information Relating to Cutting Blades

Guidelines for Correct Cutting

Initially, a new blade should be broken in. This is achieved by using the blade very carefully for 15-

20 cutting operations on a hose size which does not demand the full capability of the machine.

It is essential that the hose is forces to bend away from the blade using the provided hose support

pillars. It is also essential that the bend is symmetrical about the cutting edge.

When cutting a hose the hose must not be ‘slammed’ or forced unnecessarily against the blade as

this can cause blade fracturing or cracking, leading to premature blade failure. An elevated cutting

speed will have an inversely proportional effect on the quality of the cut, and of the life of the blade.

Avoid twisting the hose during the cutting operation as this can impact the quality of the cut.

Blade Wear

Each blade is subject to high forces during normal operation and will show signs of wear over time.

It is not possible to guarantee a blade for a number of cuts or a duration of time as this is entirely

subjective and all blades will experience a different duty cycle.

The warranty of the cutting blade is extended only to defects in geometry and manufacturing, and

does not cover excessive wear or failure due to improper or abusive use.

Replacement Blades

The cutting blade is the only consumable element of the HCL mobile cutter, and is the only

element which will be readily available for spares.

It is recommended that only cutting blades obtained from the original machine supplier be used

with the machine.