Interroll Module belt conveyor SH 1100

Maintenance and repair

68

Version 1.0 (06/2022) en

Translation of original operating instructions

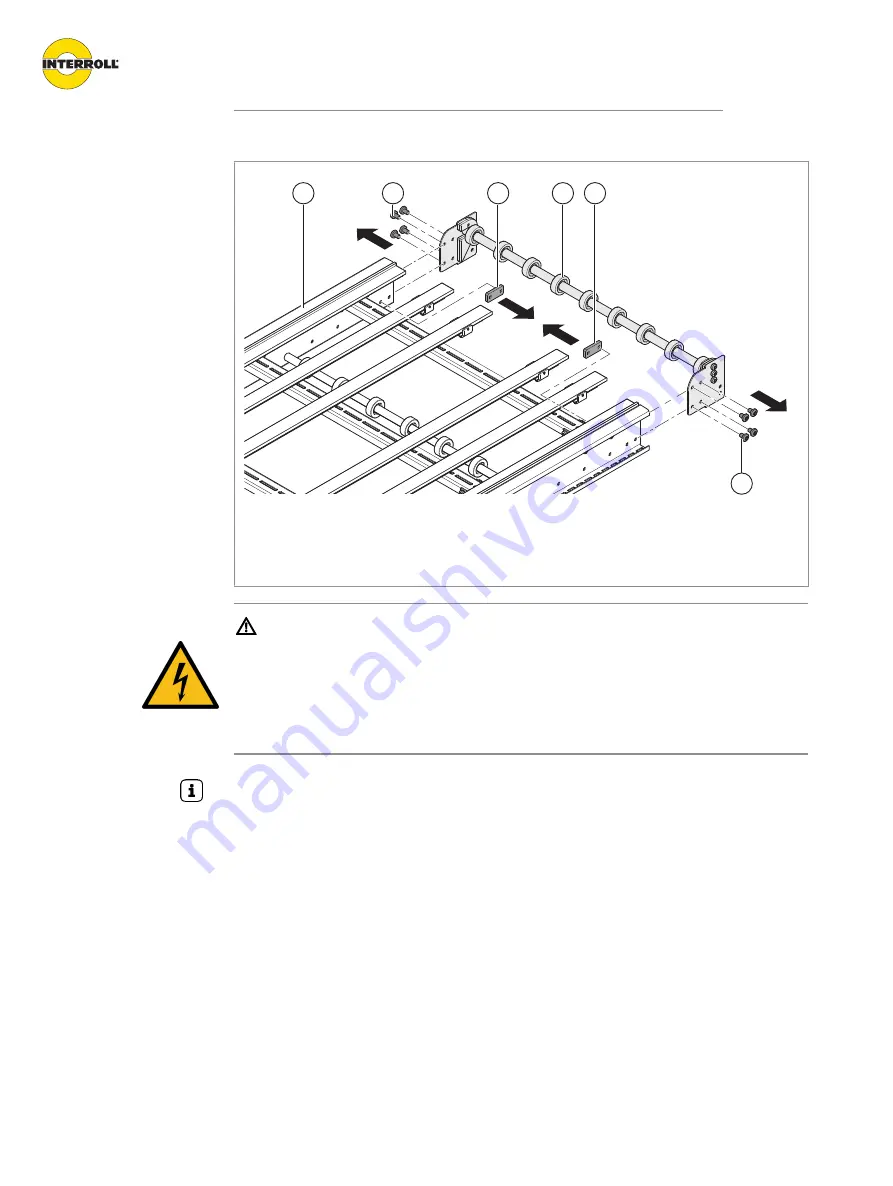

Replacing the front idler

axle

2

3

4

3

1

2

Front idler axle

1

Side frame

3

Threaded plate

2

Torx screw

4

Idler axle

DANGER

Danger to life from electrocution and crushing

Installation and maintenance tasks on 400-V conveyor systems while they are in operation can

cause life-threatening electrocution and serious crushing.

4

Power down the entire conveyor module and ensure that it cannot be started accidentally.

Fasten screws with a tightening torque of 19 Nm.

Requirement:

R

The module is shut down.

4

Remove the module conveyor,

see "Replacing the module conveyor", page 57

4

Loosen screws (2) on the right and left, remove threaded plate (3) and push idler axle (4) out

of the side frame (1).

4

Properly dispose of the old idler axle.

4

Push new idler axle (4) into the C-profile of the side frame (1).

4

Secure the idler axle (4) on the right and left with screws (2) and threaded plates (3).

4

Install the module conveyor in reverse order.