14

Line Voltage Wiring

WaRnInG:

to avoid electric shock, personal injury, or death,

turn off the electric power at the disconnect or the

main service panel before making any electrical

connections.

• Electrical connections must be in compliance with all

applicable local codes with the current revision of the

National Electric Code (ANSI/NFPA 70).

• For Canadian installations the electrical connections

and grounding shall comply with the current Canadian

Electrical Code (CSA C22.1 and/or local codes).

It is recommended that 115VAC line voltage be supplied

to the furnace from a dedicated branch circuit containing

the correct fuse or circuit breaker for the furnace as listed

in Table 6, (page 16).

IMPoRtant notE:

Refer to the wiring diagram inside the control box

cover or

for the wiring of your particular unit. any other wiring

methods must be acceptable to authority having

jurisdiction.

cautIon:

label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

IMPoRtant notE:

Proper line voltage polarity must be maintained in

order for the control system to operate correctly.

Verify the incoming neutral line is connected to the

white wire and the incoming “hot” line is connected

to the black wire. the furnace will not operate unless

the polarity and ground are properly connected as

shown in

.

Route all electrical wiring to the left side of the furnace.

See

. For installation of A-size Cabinet furnaces,

allow sufficient slack in the wiring if an optional cooling

coil cabinet is added at a later time.

use of copper

conductors is recommended.

Connecting Power Supply Wires

1. Remove the furnace control panel cover.

2. Route wires (115 VAC) through the strain relief on the

left side of the furnace control box (

3. Connect the

hot

wire to the

black

pigtail lead, and

the

neutral

wire to the

white

pigtail lead. Secure all

connections with suitable wire nuts.

4. Connect the

ground

wire to the grounding screw.

5. Reinstall the control panel cover and secure with the

original mounting screws.

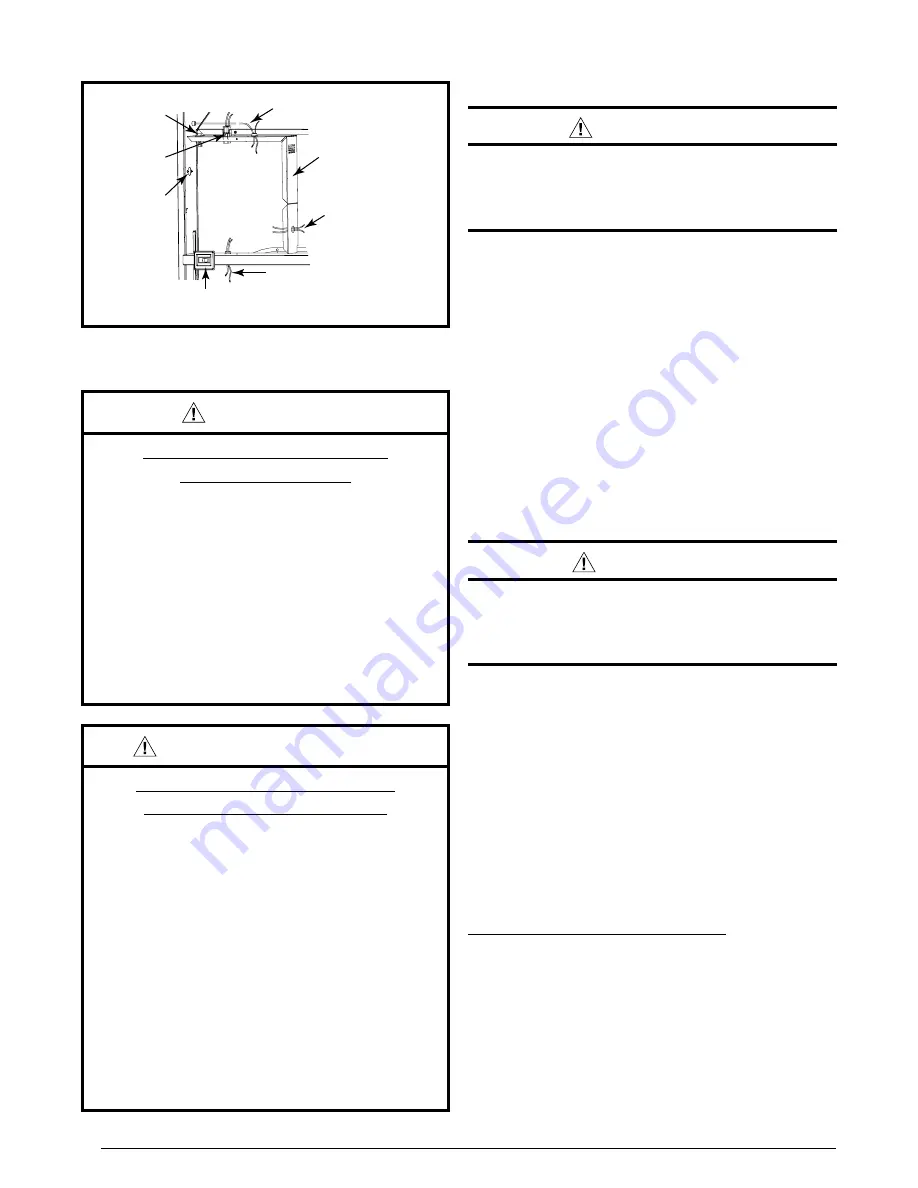

Figure 24

Figure 24. control Panel (all Models)

On-Off

Switch

Blower

Plug

Power

Entry

On-Auto Switch

(Heating Models Only)

Thermostat Wires

Furnace

Control Box

To combustion

Blower or Flame

Roll-out Switch

To Gas Valve

or Burner

ElEctRIcal InFoRMatIon

WaRnInG:

ElEctRIcal sHocK, FIRE oR

EXPlosIon HaZaRD

Failure to follow safety warnings exactly could

result in serious injury or property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

• Before servicing, disconnect all electrical

power to furnace.

• When servicing controls, label all wires prior

to disconnecting. Reconnect wires correctly.

• Verify proper operation after servicing.

aVERtIssEMEnt:

RIsQuE DE cHoc ÉlEctRIQuE,

D’IncEnDIE ou D’EXPlosIon

le non-respect des avertissements de sécurité

pourrait entraîner un fonctionnement dangereux

de l’appareil, des blessures graves, la mort ou

des dommages matériels.

un entretein incorrect pourrait entraîner un

fonctionnement dangereux de l’appareil, des

blessures graves, la mort ou des dommages

matériels

• couper toute alimentation électrique au

générateur d’air chaud avant de prodéder aux

travaux d’entretein.

• au moment de l’entretien des commandes,

étiquetez tous les fils avant de les débrancher.

s’assurer de les raccorder correctement.

• s’assurer que l’appareil fonctionne

adéquatement aprés l’entretien.