6

INS

TA

LL

ATI

O

N

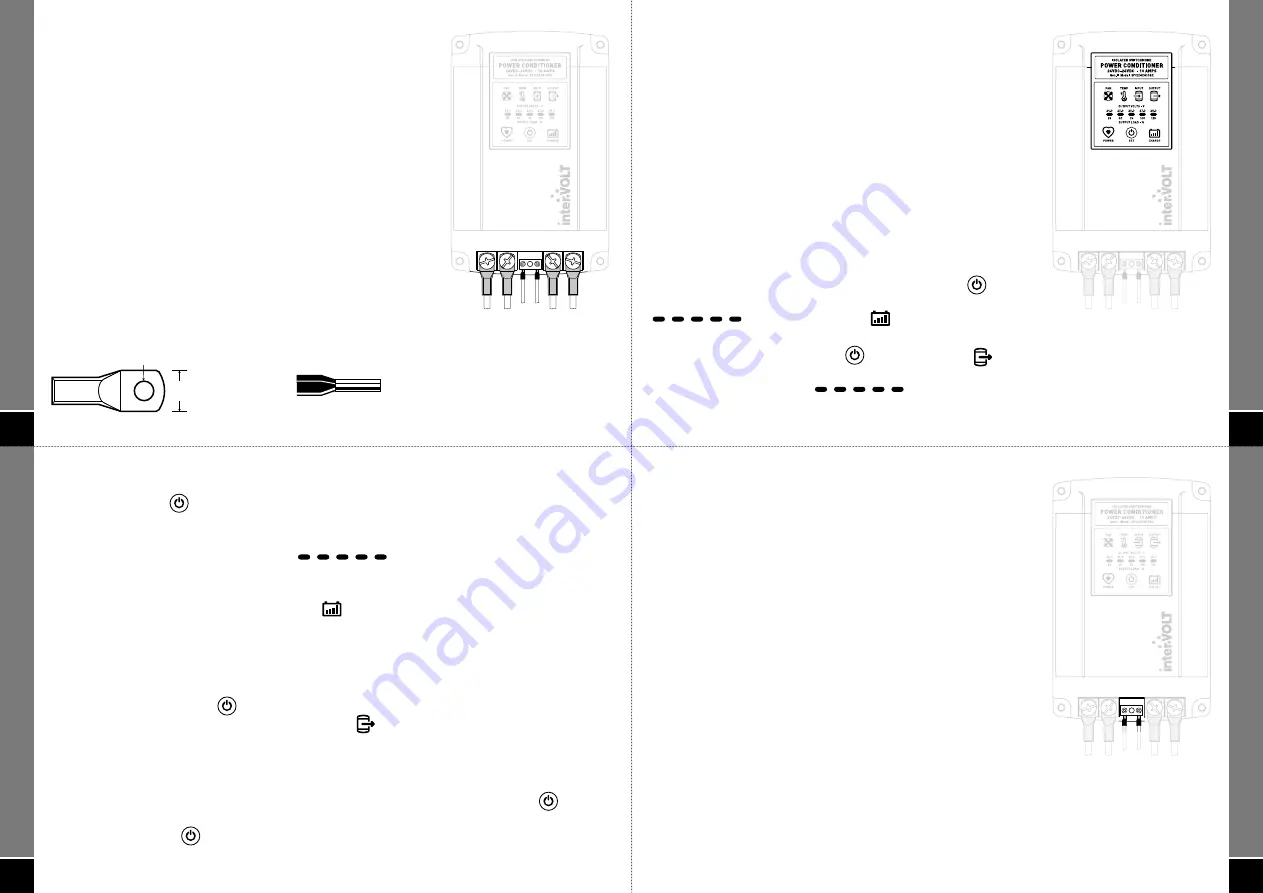

Auxiliary Terminal Block: The auxiliary terminals are optional and not

required for operation of the SPCi, however they do provide some very

useful functions. Please refer to pages 9-10 for details of the specifi c

control and monitoring functions of the auxiliary circuits.

When connecting any of the optional auxiliary circuits (terminal block)

the wiring used is for low power circuits and should be wired according

to the schematic on pages 14-15. For reference purposes the maximum

current for each of the connections is as follows:

• Terminal A: This is the external alarm output connection and is

limited to 250mA @ input voltage i.e. 24VDC nominal.

• Terminal R: This is the remote control input and is signal current

only. Supply is 8-32VDC via a control switch.

When wiring to the auxiliary terminal block it is recommended that

proper boot-lace or ferrule type crimp connectors are used (see below).

The terminating tunnels in the auxiliary terminal blocks are a cage type

and do not need excessive force to make good contact. Do not over-

tighten the terminal screw.

12mm

MAX

5.0-6.0mm

COPPER LUG

BOOT-LACE FERRULE

4.0mm

diameter

MAX

2.0mm

diameter

MAX

INPUT

AUX.

+24V –0V

R

A

+24V

-0V

OUTPUT

INPUT

AUX.

+24V –0V

R

A

+24V

-0V

OUTPUT

8

Step 2 – Changing Output Setting

Press the SET button

again to scroll through the display incrementally to select the desired

setting for your specifi c application as follows:

• For use as a power conditioner the output setting can be adjusted between 24.0V and 28.0V in

1V increments on the OUTPUT VOLTS bar

display. It is important to ensure

the equipment connected to the output of the SPCi is correctly rated for the voltage you have

selected.

• For use as a battery charger the CHARGE icon

must be selected which changes the output

from a continuous DC regulated supply to a special two stage charging protocol (sample curve

data available upon request). The two stages consist of a boost cycle of 28.8V and a fl oat cycle of

27.2V. These voltages are not adjustable.

Step 3 – Saving Output Setting

Simply release the SET button

at the desired point and the output will adjust automatically to

the new setting after a few moments. The OUTPUT icon

will pulse rapidly and then disappear

indicating the setting has been successfully saved.

The new setting will be displayed for a further 10 seconds as confi rmation of the new setting. The

selected setting will now be permanently memorised but can be changed at any time if necessary.

NOTE:

The factory default settings can be reset at any time. Press and hold the SET button

for 30 seconds until all icons on the operator interface display are illuminated (pulsing).

Release the SET button

and the factory default settings will be restored at which point the

illuminated icons will disappear.

OP

ER

AT

ION

7

OP

ER

AT

ION

OPERATION

INITIAL SET-UP

One of the major features of the Gen II SPCi is the ability to adjust

the output voltage when used as a conditioner or alternatively,

select a two stage voltage curve when used as a battery charger

(lead acid only).

As detailed in the wiring section, the output voltage of the SPCi

should ideally be selected before connecting the output supply

to the 24V equipment or battery. The SPCi output can however,

be adjusted at any time providing there is power on the input and

NO load on the output.

The output voltage cannot be adjusted in battery charging mode.

IMPORTANT: A battery should only be connected to the SPCi in

battery charging mode and NOT in power conditioner mode.

Step 1 – Enter Output Set-Up Mode

To adjust the output voltage press and hold the SET button

for 5 seconds until the 5 bars of the OUTPUT VOLTS indicator

and the CHARGE icon

are illuminated

intermittently (fl ashing).

At this point release the SET button

. The OUTPUT icon

and the factory default voltage setting of 26.0V is displayed on

the OUTPUT VOLTS indicator

.

INPUT

AUX.

+24V –0V

R

A

+24V

-0V

OUTPUT

INPUT

AUX.

+24V –0V

R

A

+24V

-0V

OUTPUT

9

OP

ER

AT

ION

EXTENDED FEATURES

The GEN II SPCi has a range of optional features which can be

utilised for control and monitoring purposes.

These functions are enabled through the use of the auxiliary

terminal connections. This is a Euro style terminal block located

between the input and output terminals of the SPCi.

The Euro style terminal block is a high quality two pole connector

used to terminate separate remote monitoring and control or

auxiliary functions. There are no ferrous components in the

terminal block so there is much less risk of corrosion which results

in poor contact.

Please refer pages 14-15 for schematics of the various wiring

circuits available.

External Alarm Output

This output (terminal A) is used for remote monitoring of the pre-

emptive and shutdown alarms of the SPCi. Subsequently any alarm

condition displayed on the operator interface display of the SPCi can

also be remotely monitored i.e. cooling fan fault, unit overheating,

low input voltage, output overload or short circuit.

Generally the output would be connected to a remote sounder/indicator but can also be used to activate a

relay coil to switch a larger warning device. It is important to note that the maximum power of the Alarm

output is limited to 250mA @ input voltage i.e. 24VDC nominal.

INPUT

AUX.

+24V –0V

R

A

+24V

-0V

OUTPUT

INPUT

AUX.

+24V –0V

R

A

+24V

-0V

OUTPUT