10

m i n .

m a x .

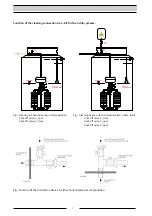

Fig.:

Cleaning

container

AL

‐

Tank

60L

for

single

membrane

station

(right:

without

aeration

distributor)

Example:

Cleaning

AQUALOOP

membrane

station

(2

‐

6

membranes):

Be

sure

the

room

in

which

the

cleaning

takes

place

is

well

ventilated!

The

pumps

are

connected

to

the

integrated

control

unit

as

described

in

section

7.

Input

24 VD

C

Ø 493

Ø 493

126

0

126

0

Ø 740

Ø 740

DN5

0

Fig.:

Cleaning

container

AL

‐

Tank

350L

for

2

‐

6

membranes

station

with

integrated

control

unit

1.6.2.3

Cleaning

solution

We

recommend

the

cleaning

solution

to

be

made

from

regular

domestic

cleaning

agents

and

should

be

mixed

as

following

(example

for

In

‐

Situ

cleaning):

1)

Acid

cleaning

against

deposits

such

as

calcium

carbonate

Citric

acid

(target

cleaning

solution

1%

acid):

a.)

Available

in

most

stores

as

granulate

packets

Dissolve

20

g

per

AL

membrane

cartridge

in

2

L

warm,

clear

water

(30°C).

b.)

Available

in

most

stores

also

as

liquid

concentrate

(e.g.

as

30%

acid

solution)

Dilute

69

ml

per

AL

membrane

cartridge

in

2

L

warm,

clear

water

(30°C)

to

achieve

a

cleaning

fluid

concentration

about

1%!