5

Fig.

:

External

ring

with

arrow

marking

on

OPEN

position

Fig.

:

Opened

membrane

Replacing

the

filter

element:

It

is

recommended

that

the

filter

element(s)

is

cleaned

or

replaced

depending

on

running

time

and

the

surrounding

air

quality.

The

filter

element(s)

should

be

checked

every

6

months

and

should

be

replaced

every

4

years.

Detailed

information

can

be

found

in

the

separate

blower

instruction

manual

(MEDO

LA

Blower)

–

available

from

your

local

Distributor.

Replacing

the

piston

set

assembly:

It

is

suggested

that

the

Piston

Set

Assembly

is

replaced

every

24

months

or

after

20,000

h

depending

on

the

performance

of

the

blower´s

pressure

and

airflow

delivery.

There

is

a

groove

on

each

Teflon

seal

of

the

piston

indicating

the

degree

of

wear.

If

one

or

both

grooves

are

worn

away,

replacement

of

the

Piston

Set

Assembly

is

recommended.

Detailed

information

can

be

found

in

the

separate

blower

instruction

manual

which

is

included

with

the

blowers.

1.6

Membrane

1.6.1

Mechanical

cleaning

of

the

membrane

It

needs

to

be

determined,

based

on

the

amount

of

sludge

present

in

the

bottom

of

the

bioreactor,

whether

a

full

external

spray

‐

down

of

the

membranes

is

necessary

at

maintenance

time.

Check

the

sludge

level,

and

if

sludge

can

be

easily

seen,

or

measures

1cm

or

more

on

the

bottom

of

the

tank

then

the

system

should

be

shut

down,

the

membrane

station

with

membranes

attached

removed

from

the

tank,

and

the

membranes

detached

from

the

membrane

station

and

cleaned

as

described

in

this

chapter.

CAUTION:

Take

care

not

to

lose

any

of

the

O

rings

or

fibre

Washers

that

are

connected

at

each

end

of

the

membranes

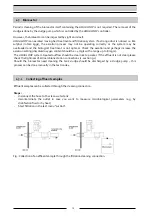

Sludge

that

has

accumulated

on

the

outside

of

the

fibres

(inside

the

blue

cartridge)

can

be

mechanically

washed

with

a

jet

of

water.

The

outer

ring

is

rotated

from

the

LOCK

position

to

the

OPEN

position

(counter

clockwise)

to

open

the

cartridge.

The

grey

underside

of

the

membrane

must

be

held

secure.

The

outer

grey

ring

can

be

removed

in

the

OPEN

position.

Then

the

blue

external

cover

is

free

to

be

removed

from

the

top.