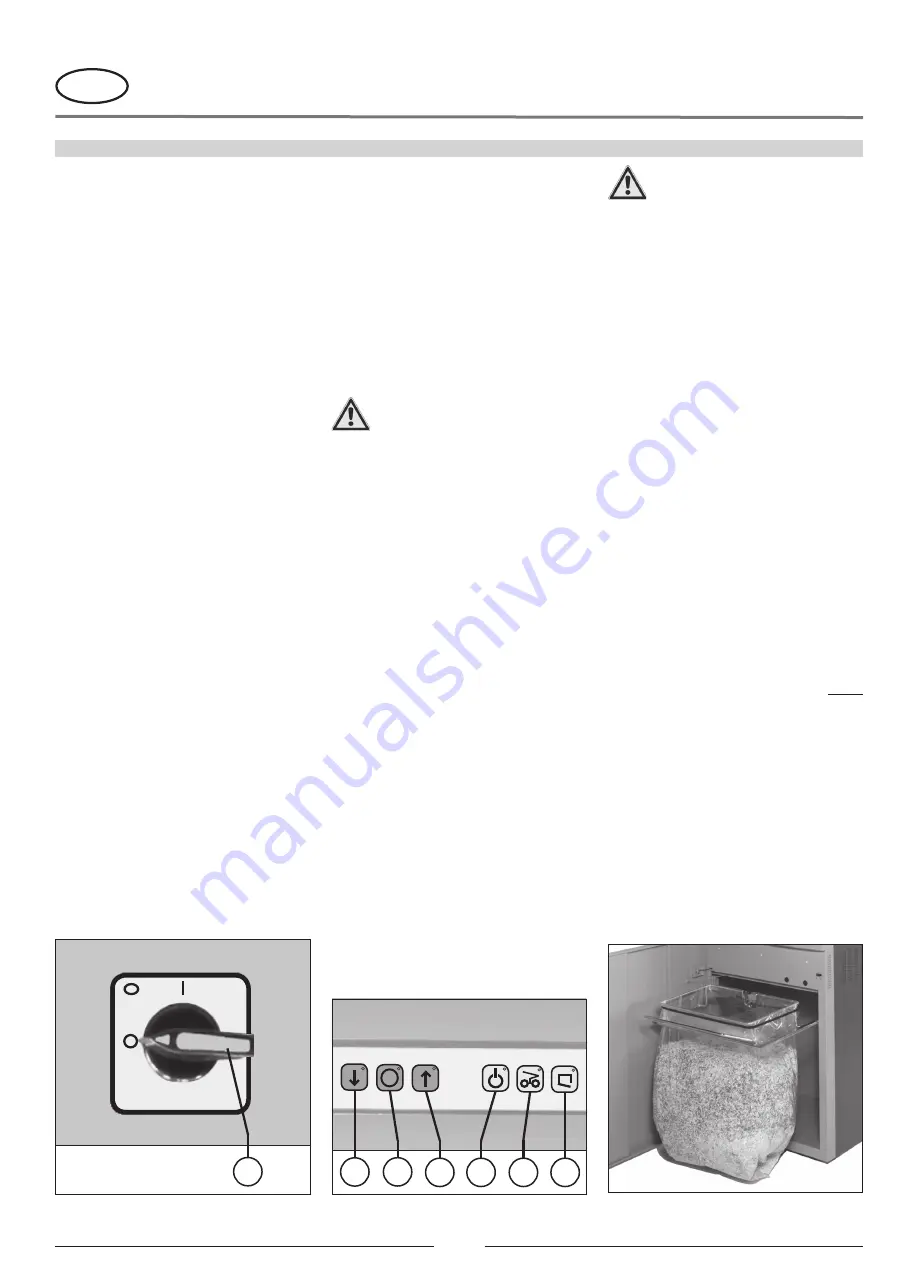

OPERATING FUNCTIONS (Figs. 1, 2 and 4):

1 = Mains switch (Emergency-stop) (fig. 1)

This switch turns the machine either on (po-

sition „1“) or off (position „0“).

2 = „Cutting system forward“

pushbutton (fig. 2)

Pressing this button starts the cutting system.

Material can now be fed to the shredder.

Note: Press and hold button for approx. 1

sec.

3 = „Cutting system stop“

pushbutton (fig. 2)

Pressing this button switches the shredder

off, thereby halting the cutting system.

4 = „Cutting system reverse“

pushbutton (fig. 2)

Pressing this button starts the cutting system

in reverse.

Note: Press and hold button for approx. 1

sec.

5 = Pilot lamp (fig. 2)

a) „ready“

Continously lights when the mains switch

(1) is operated.

b) „motor protection“

Flashes when the motor is overloaded.

The machine cannot be started during the

cooling down phase of the motor. Additional

the pilot lamp of the control display (7) (fig.

2) lights up.

6 = Pilot lamp „paper jam“ (fig. 2)

Lights when too much paper is fed to the

cutters (see description „AUTOMATIC RE-

SPONSE IN CASE OF OVER-LOADING“).

7 = Pilot lamp (fig. 2)

a) „door open“/„hopper open“

Lights when the door is not closed or when

the hopper is open. The machine then

switches off automatically and it cannot

be started as long as the door is open or

the hopper is open.

Note: To turn the machine into the „Rea-

dy“- mode again after an interruption, there

must be operated both end switches at

the corresponding turn-off device. For this

the door must be openend before not less

than 10 cm or the hopper must be folded

upwards with a minimum of 10 cm.

b) „collecting bag full“ (fig. 2)

Lights as soon as the collecting bag is full

and needs to be emptied. At the same time

the machine switches off automatically.

8 = Light barrier (forward operation) (fig. 5)

The shredding operation is started as soon

as a sheet of paper passes through the feed

slot.

OPERATING THE MACHINE:

To start, switch on the unit by operating the mains

switch (1) (fig. 1). The pilot lamp marked „ready

for operation“ (5), as well as the red stop-button

„S“ (3) (fig. 2) will light to indicate that the machine

is ready for operation.

The paper tray may not be used as

a step ladder or as a seat. Danger of

tipping over!

FEEDING CRUMPLED PAPER:

1. Fill the hopper with crumpled paper.

Note: The crumpled paper can be dropped

directly from the wastepaper basket into the

hopper of the machine. The apportioning wings

preceding the cutting mechanism ensure more

or less uniform distribution of the paper.

Attention:

The wastepaper basket is no refuse

tin and should not be emptied into the machine

thoughtlessly - in no way can the machine

destroy bottles, pens, pencil sharpeners etc.

2. Press the pushbutton switch „forward“ (2) (fig.

2). The cutting system runs and begins to shred

the paper.

Note: Do not feed any smooth paper until the

crumpled paper is completely shredded.

3. To switch the machine off press the red stop-

button (3) (fig. 2).

FEEDING SMOOTH PAPER:

- Feed smooth paper through the opening at the

lower part of the hopper to the cutting system.

- Machine switches automatically to forward and

draws paper in.

- The machine switches off automatically after

shredding.

Never feed the shredder with a quantity

of paper exceeding the maximum indi-

cated in the technical details.

Should the machine be overfed, follow

the instructions under „AUTOMATIC RE-

SPONSE IN CASE OF OVERLOADING“.

AUTOMATIC RESPONSE

IN CASE oF „ovERLoADING“:

In case you accidentally overload the shredder,

it will automatically alleviate the problem as

follows:

1. The cutting system becomes jammed. The pilot

lamp (6) (fig. 2) lights up.

2. The cutting system runs briefly in reverse,

thereby freeing the material to be shredded.

3. The cutting system automatically switches back

to forward mode.

The machine repeats this process until all the

material has been shredded satisfactorily.

EMPTYING THE COLLECTING BAG (Fig. 4):

When the collecting bag is full, the machine turns

off automatically. The pilot lamp (7) (fig. 2) lights

up. Empty the collecting bag as follows:

- Open the door and take out the sliding frame

with the collecting bag.

- Remove the rubber band, take out the full bag

and dispose of contents.

- Put the empty bag from below through the sliding

frame and put the edges of the bag approx. 10

cm over the frame outwardly.

- Fix the collecting bag with the rubber band at

the sliding frame.

- Move back the sliding frame with the collecting

bag and close door.

Note: The machine will only run with closed

door!

Fig. 1

Fig. 2

Fig. 4

93165 3 10/16

3

2 5

6 7

4

S

I

1

OPERATION

GB

MAINS SWITCH

6

Translation of the Original Operation Manual

Übersetzung der Originalbetriebsanleitung