INDUSTRIAL SHREDDER

Instruction manual for use and maintenance

MSM0005EN_

F

22 / 90

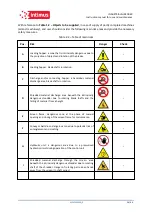

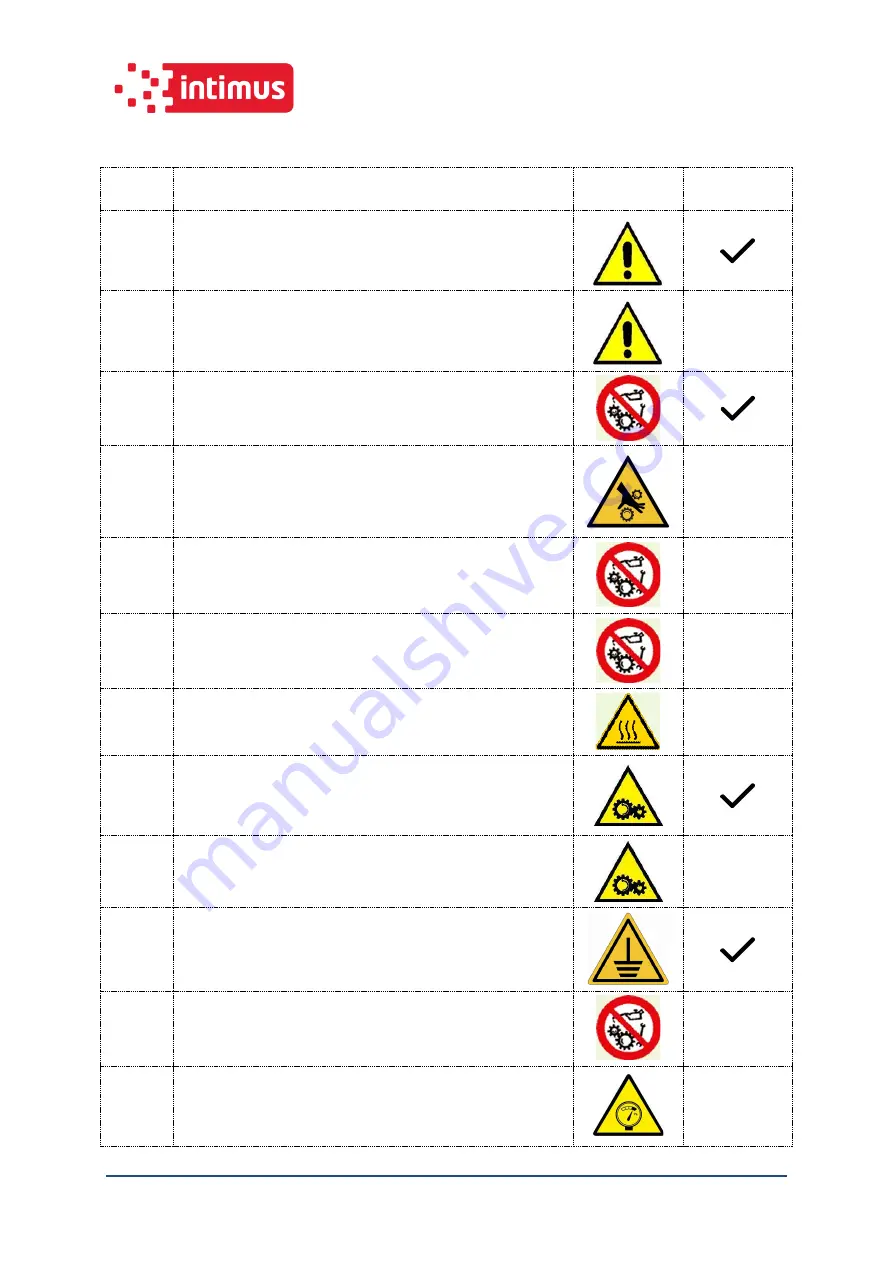

Table 2-1- Table of risks, dangers and protection measures present

Pos.

Description and protection from risks

Danger

Check

1

Feeding hopper with loading drawer: conveys the material to

the shredding chamber and prevents access to an intrinsically

dangerous area in compliance with safety distances.

2

Load hopper cover with PVC sheeting: this prevents the

projection of the material outwards during the shredding

phase.

-

3

Support stand with panels and doors with protective grid: they

prevent the shredded material from being projected and the

dangerous area from being accessed unintentionally.

4

Rotor protection casing: they prevent the access of limbs to an

area with dangerous rotating parts (other series).

-

5

Motor joint protections: they prevent the access of limbs to an

area with rotating parts (other series).

-

6

Motor joint protections (bell): they prevent the access of limbs

to an area with rotating parts (hydraulic control units).

-

7

Grid protection of planetary gearbox: it protects from the

potentially hot surface of the planetary gearbox (optional)

-

8

Key safety micro-switch: it stops operation of the machinery

once the frame doors and the loading hopper inspection door

are opened in order to determine the state of the shredding

chamber (the latter where present).

9

Cable safety micro-switch: it stops operation of the machinery

when the operator is working on the cable (typical use on

conveyor belts).

10

Copper braid: it ensures continuity of the equipotential

protection circuit fixed between the components of the system.

11

Motor belt cover: it protects against fast rotation parts such as

motor pulleys and the corresponding motor drive belts (other

series).

-

12

High pressure hose retaining system (metal cable): it prevents

the violent leaking of the hydraulic oil in operation from the

high pressure pipes on motors and hydraulic pumps, which

causes hose whiplash.

-