INDUSTRIAL SHREDDER

Instruction manual for use and maintenance

MSM0005EN_

F

33 / 90

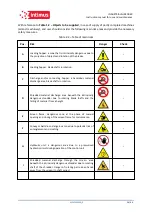

Table 2-6 – Personal protection equipment for maintenance technicians

Use of a safety helmet with

a chin strap

Protective clothing and leather

leggings

Use protective anti-cut

gloves for chemical and

mechanical use

Use safety footwear for

accident prevention

Protect hearing

Obligation to use a seat belt,

for operations at height, during

maintenance

Protect eyes

Obligation to protect the

respiratory tract, during

maintenance, against the risk

of gas, vapours and dust

The designated operator must work with garments that are able to offer adequate protection against

potential risks (chemical, physical and/or microbiological) due to contact with a wide variety of

materials including liquids and gases.

These means must be suitable, in terms of materials and structure, to prevent any danger of

contact/contamination. It is the responsibility of the user to guarantee, in compliance with the

regulations in force in the country where the machine is being used, the use of means with the highest

degree of protection in relation to the type of processing material.

The protection means to be adopted must be able to allow sufficient freedom of movement to perform

the envisaged operating manoeuvres. Regarding visual perception, these means must be able to

preserve the widest angle with the least distortion.

Use only certified and approved protective equipment.

The protection means must be correctly used and maintained (e.g. correct wearing and tightening of

closures, replacement of filters in masks, etc.)