Operation Manual 5280 EPSP

60

•

DANGER!

Caution – Fire hazard with insufficient ventilation!

The machine guards must be put back into place immediately after

maintenance work has been completed!

9.3 Lubrication

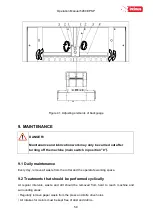

The list of lubrication points is shown in Figures 44, 45, 46, 47, 48 and described in table 10.

Access to lubrication points is possible after removing the covers shown in Figs. 42, 43, 46,

48. When lubricating the knife assembly, use the controls as when changing the knife

(Chapter 8.1). In places requiring lubrication with a grease, apply grease with a grease gun.

It is enough to press the trigger of the lubricator 2-3 times.

The indicated points should be lubricated once a week!

Table 10. List of lubrication points of the cutter mechanisms

Mark

Cutter

mecha

nism

Type of

lubricant

Lubrication point

Figure

Knife

Grease

•

Side surfaces of the guides (in contact with

the knife body)

•

Internal surfaces of guides (in contact with

rollers)

•

Side surfaces of the knife body

44,45

Backgu

age

Oil

•

guide roller (apply a thin layer of oil.)

•

lead screw (apply a thin layer of grease)

45

46

Clamp

Grease

• the pressure beam slides

• shaft bearings

• the surface of the gears

• tie rod - pin

• gear bearings 2 (fig.47)

45

47

47

47

48

1

2

3