Operation Manual 5280 EPSP

16

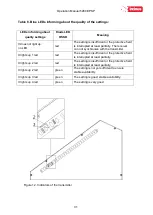

4.

The screw mechanism of the

backguage drive

cutter body

fixed cover

2

6

5.

Motor, lever mechanism of

the knife drive mechanism

fixed cover

front table

Emergency stop

3, 4, 1

2

10

6. Approach move of the

clamping beam

fixed cover

electro sensitive

protective device

two-handed device

−

Emergency stop

1

7

5

10

7. Approach move of

backguage

fixed cover

Emergency stop

6

10

8. Cutting zone

two-handed device

electro sensitive protective device

cam device that monitors the knife

stop at the upper turning point

Emergency switch

5

7

9

10

9. Manipulation with a knife

during its replacement

transport handles

special protective packaging

10. Sharp edges and corners of

the cutter elements

refraction, dullness, rounding

11. Uneven or rough surfaces

precise workpiece machining

paint coatings

II

ELECTRICAL

1. Direct contact of active

elements

closed housing

partially reduced voltage supply to the

control system up to 24V AC/DC.

3,4

2 Indirect touch

protection against indirect contact

according to PN-EN 60204-1

continuity of the protective conductor

2.8 Safe working rules

1. training of the operator:

• aware of the potential hazards that may occur when operating the cutter

• clearly defining activities which, under the conditions of a given plant, are or are not the

responsibility of the cutter operator and are reserved for designated authorized persons, in

particular as regards the removal of defects and repairs - including electrical installations.

2. prohibition to use the cutter if:

• the machine is used contrary to its intended use and/or the cutting parameters specified in

the operating instructions would be exceeded

• the cutter is visibly inefficient

• any covers of moving parts have been removed from the cutter