Operation Manual 7310 EPSHP

10

Info

Before operating the cutter the operator must read the operating instructions.

•

Every employee delegated to work during assembly, disassembly, reassembly,

commissioning, servicing and maintenance (technical inspection, servicing, repairs)

of the cutter must read the entire operating manual, in particular the chapter "Safety

of use".

The manufacturer recommends that the buyer of the machine, transferring it for use,

obtained a written confirmation of the contents of the instructions.

•

Every employee authorized to perform assembly, start-up, operation and

maintenance and repair of the cutter must read the entire operating manual, in

particular the chapter "Safety rules".

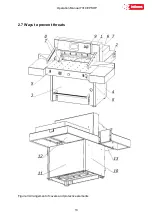

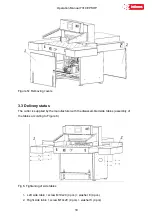

2.3 Requirements for the operator's workplace.

The user is obliged to create working conditions at the cutter workplace that preclude

the operator from slipping, slipping or falling due to poor ground conditions, the way

of routing the wires or the lack of convenient access!

2.3.1 Personal protection equipment

If necessary or if it results from the regulations in force, use the following personal protective

equipment:

•

Wear safety shoes

•

Wear safety goggles, e.g. when cutting fragile material

•

Use hearing protection, e.g. when cutting hard material

2.3.2 Permissible environmental and operational conditions

•

Operation of the machine is permitted in closed rooms

•

Humidity: 35% - 95% (non-condensed)

•

Ambient air temperature: + 5 °C - + 30 °C

2.4 Expected risks when operating the cutter

Using the single cutter as intended, you can predict some of the risks to your life and health.

To avoid existing hazards, the rules of using and operating the cutter must be explained in

detail. Special attention should be paid to the cutter units and situations posing a threat to the

operator and third parties:

DANGER!

The operator can operate the machine in good technical condition.

At the beginning of each work shift and after each knife replacement, check the operation of

the safety devices. Interference in security or bypassing them (eg safety light curtains, two-

handed controls) creates a danger to life or injury!

At the moment, the cutter can only support one operator!

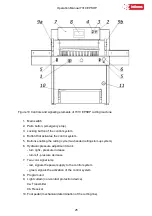

Summary of Contents for INT-GU-07310EPSHP

Page 5: ...Operation Manual 7310 EPSHP 5 EC Conformity Declaration...

Page 42: ...Operation Manual 7310 EPSHP 42 Figure 26 Figure 27...

Page 55: ...Operation Manual 7310 EPSHP 55 Figure 43 Adjusting elements of backguage...

Page 61: ...Operation Manual 7310 EPSHP 61 Figure 50 Lubrication point of the knife assembly lever...

Page 66: ...Operation Manual 7310 EPSHP 66 PROGRAM MODULE OPERATOR MANUAL DOP B07S410 7...