Operation Manual 7310 EPSHP

34

7.4.1 Changing the position of the beam with the handwheel

1. Press knob 2 (Fig. 17)

2. Turn the knob to bring the beam closer or closer by reading the position value on the

programmer screen.

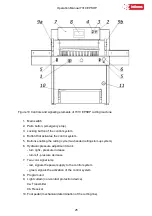

Figure 17 Arrangement of the positioning elements of the backguage

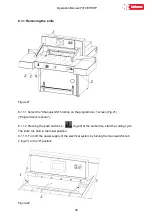

7.5 Pressing the material

The pressing of the cut material takes place automatically after pressing the buttons that start

the cutting cycle 1 (fig. 18).

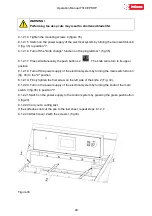

DANGER!

Do not put your hands into the cutting area when pressing!

7.5.1 Manual clamping of cut material (mechanical cutting line determination)

Lower the pressure beam onto the stack by pressing the pedal 2 (Fig.18). The front edge of

the clamping bar is the same as the cutting line. Therefore, it can be used as an indicator of

the cutting line. The clamp can be stopped in any position.

Summary of Contents for INT-GU-07310EPSHP

Page 5: ...Operation Manual 7310 EPSHP 5 EC Conformity Declaration...

Page 42: ...Operation Manual 7310 EPSHP 42 Figure 26 Figure 27...

Page 55: ...Operation Manual 7310 EPSHP 55 Figure 43 Adjusting elements of backguage...

Page 61: ...Operation Manual 7310 EPSHP 61 Figure 50 Lubrication point of the knife assembly lever...

Page 66: ...Operation Manual 7310 EPSHP 66 PROGRAM MODULE OPERATOR MANUAL DOP B07S410 7...