Operation Manual 7310 EPSHP

53

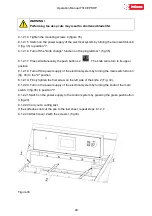

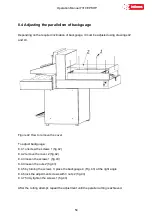

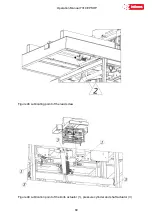

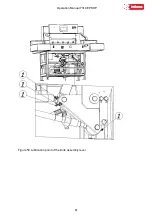

8.3.2 Pressing pedal 2 (Fig. 41), bring the pressure beam down so that the insert pins hit the

holes in the beam and the insert adheres the entire surface to the bottom surface of the

beam.

8.3.3 Use a 3-mm hexagonal key with 3 mm to firmly screw in the screws 3 (Fig. 41) in the

threaded holes in the clamping beam, causing the insert to be blocked in the clamping beam.

8.3.4 Release the pressure on the pedal 2 (Fig. 41) - the beam with the inserted insert

returns to the upper position

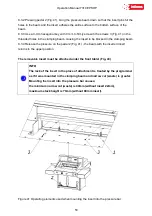

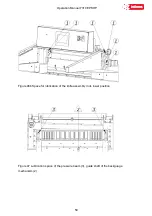

The removable insert must be attached under the front table! (Fig. 40)

INFO

The lack of the insert in the place of attachment is treated by the programmer

as if it was mounted in the clamping beam and narrow cut (waste) is greater.

Mounting the insert into the pressure bar causes;

the minimum narrow cut (waste) is 40mm (without insert 22mm),

maximum stack height is 76mm (without 80mm insert).

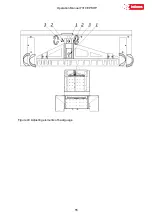

Figure 41 Operating elements used when mounting the insert into the pressure bar

Summary of Contents for INT-GU-07310EPSHP

Page 5: ...Operation Manual 7310 EPSHP 5 EC Conformity Declaration...

Page 42: ...Operation Manual 7310 EPSHP 42 Figure 26 Figure 27...

Page 55: ...Operation Manual 7310 EPSHP 55 Figure 43 Adjusting elements of backguage...

Page 61: ...Operation Manual 7310 EPSHP 61 Figure 50 Lubrication point of the knife assembly lever...

Page 66: ...Operation Manual 7310 EPSHP 66 PROGRAM MODULE OPERATOR MANUAL DOP B07S410 7...