Maintenance

19

i

BA 14.105/115 EN 2.0

5

Maintenance

The clutches and brakes are largely free of maintenance. In applications requiring many switching

operations the air gap “s

Lü

” must be checked and readjusted at certain periods. When the air gap

has reached 250% of its rated value “s

Lü

” at the latest it must be readjusted to the rated value at

the latest.

•

For air gap setting “s

Lü

” after wear see chapter 5.1, Disassembly.

•

The shims mentioned in section 2 can be removed or the spacers can be reduced.

The friction face poles of the rotor or stator of clutches or brakes run into the armature plate.

Friction marks are thus normal and must not be re-worked!

Stop!

Friction faces must be kept absolutely free of oil and grease!

5.1

Disassembly

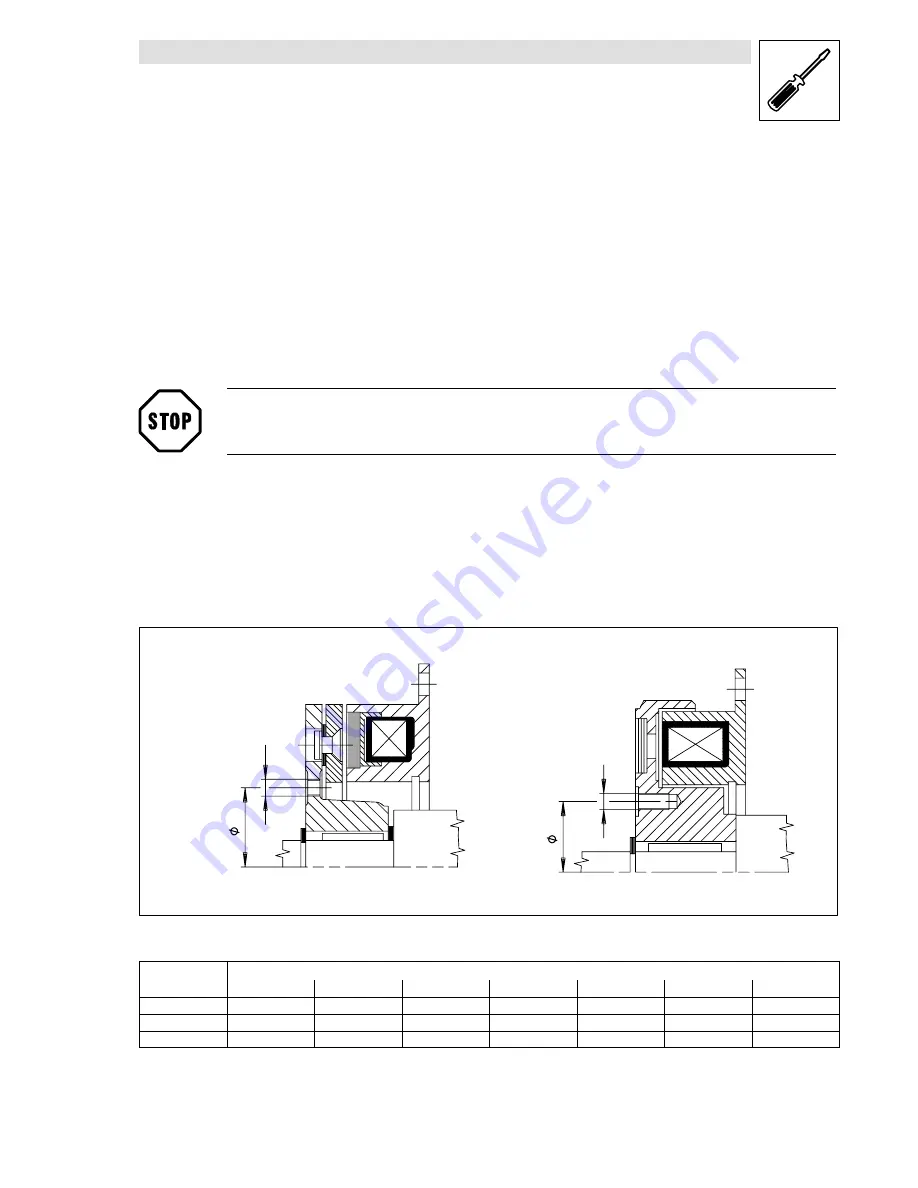

Remove the axial circlip or shaft locking plate Fig. 9 to disassemble the armature assembly of

design 1 or 2 or the rotor. After that the armature assembly can be withdrawn from the shaft via

the withdrawal thread “d” (see Fig. 9 and Tab. 5) provided for disassembly in the flange hub or

rotor of the corresponding part. After the armature assembly has been withdrawn, remove the

shims depending on the air gap size “s

Lü

” (Fig. 6 and Tab. 3) and mount them afterwards between

circlip and flange hub.

d

e

d

c

Fig. 9

Size

06

08

10

12

16

20

25

ø c

29

36

46

56

73

92

114

d

M4

M4

M4

M4

M5

M6

M8

ø e

31

37

47

56

73

93

120

Tab. 5

Dimensions in mm