9

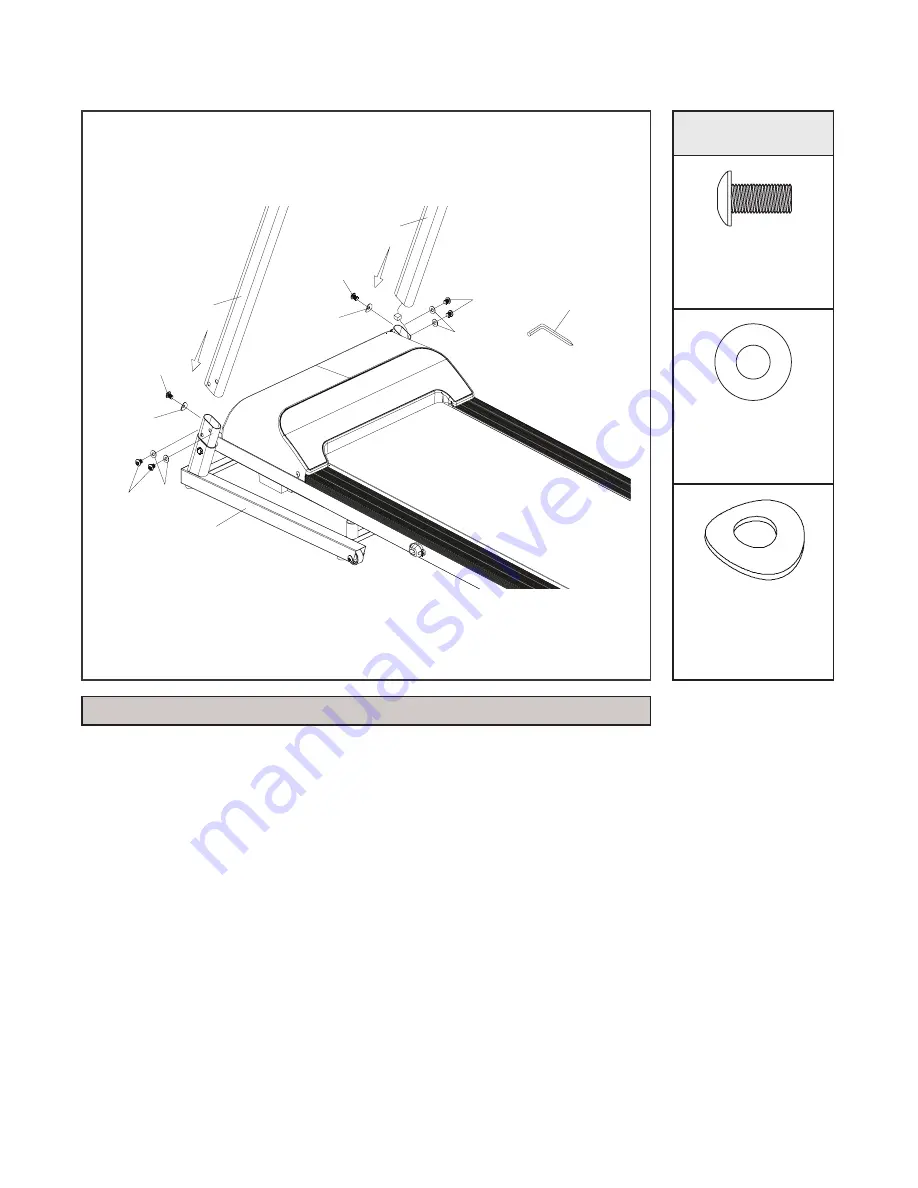

ASSEMBLY STEP 3

94

94

79

95

2

104

94

95

94

79

3

4

1. Open

HARDWARE FOR STEP 3.

2. Insert the

UPRIGHTS

(L, R)(3,4) into the

FRAME BASE

(2) with

the 6

BUTTON HEAD SOCKET BOLTS

(94), 4

FLAT WASH-

ERS

(79) and 2

CURVED WASHERS

(95) by using the

ALLEN

WRENCH

. (Please fix the screw without tightening it.)

HARDWARE

Bolt (94)

Qty: 6

Flat Washer (79)

Qty: 4

Curved

Washer (95)

Qty: 2

NOTE: this step may work better with a second person assisting.