3G Storm Series

®

Wheelchairs

68

Part No. 1104849

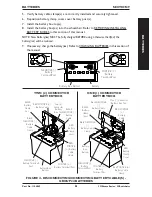

WHEELCHAIRS EQUIPPED WITH

MCC-MARK IV JOYSTICK

WHEELCHAIRS EQUIPPED WITH

MARK IV RII JOYSTICK

From

Battery

Charger

Battery Charger Connector

From Battery

Charger

Three (3)

Pronged Plug

Battery Charger

Battery Boxes

Base Frame

Battery Charger Mount Bracket

Support

Plate

Battery Charger

Port

FIGURE 7 - CHARGING BATTERIES

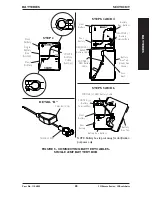

NOTE: This joystick is available only on the

Torque SP.

FRONT VIEW OF

JOYSTICK

Charger Port

Battery Charger

Three (3) Pronged Plug

From Battery

Charger

Charger

Port

Joystick

Battery

Boxes

USING BATTERY CHARGERS

1. Perform one (1) of the following:

A.

WHEELCHAIRS EQUIPPED WITH MCC-MARK IV JOYSTICK

- Attach

the battery charger connector to the charger cable/battery harness.

NOTE: The battery charger connector is factory installed on the RIGHT side of the wheelchair.

It can be positioned on either side of the wheelchair for user convenience.

NOTE FOR RECLINERS ONLY: If the wheelchair is a recliner, the battery charger connector as

well as the limit switch, are factory set on the RIGHT side of the wheelchair. However, they can

be positioned on either side for user convenience. The limit switch MUST BE positioned on the

same side as the battery charger connector.

B.

TORQUE SP EQUIPPED WITH MARK IV RII JOYSTICK -

Attach the

battery charger connector to the charger port on the FRONT of the joystick.

2. Plug the charger’s AC power cord, or extension, into the grounded 120 VAC wall outlet.

3. Wait until charging is complete.

NOTE: It is advantageous to recharge frequently rather than only when necessary. In fact, a

battery’s life is extended if the charge level is maintained well above a low condition.

NOTE: If the batteries need to be charged more often or take longer to charge than normal,

they may need to be replaced. Contact an Invacare dealer for service.

BATTERIES

SECTION 9

BATTERIES

Charger Cable