36

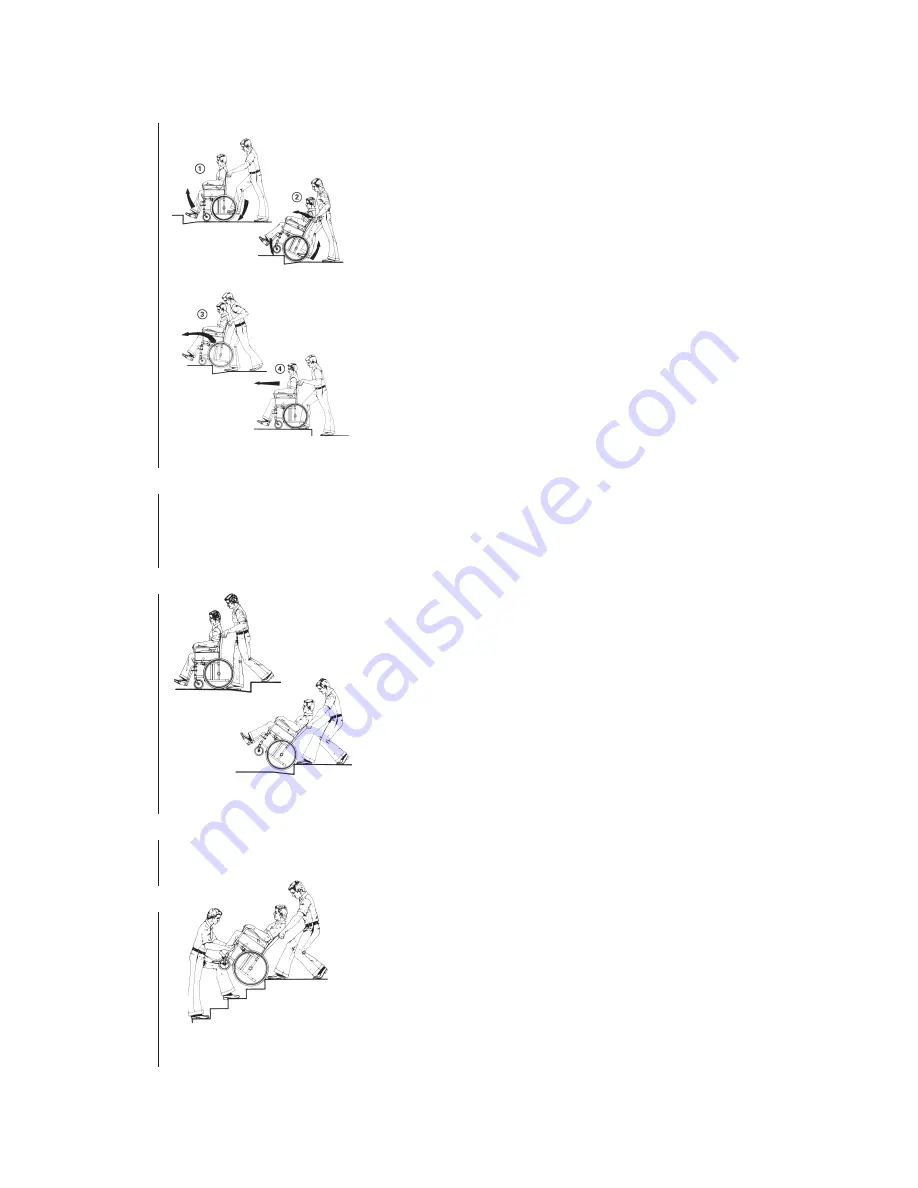

Onto a kerb

This method assumes the assistant is always behind the wheelchair and

creates the greatest safety for the user.

The following advice is for the assistant:

Illustration 1

Adjust the anti-tip devices upwards. Ensure that the user’s feet rest

securely on the foot rests and cannot slide off before you lean the

wheelchair backwards and push it forwards against the kerb.

Illustration 2

Lower the front part of the wheelchair onto the pavement and stand

as close to the wheelchair as possible before you lift up the whole

wheelchair.

Illustration 3

Lean forward and lift/roll the wheelchair over the kerb.

Illustration 4

Lower the wheelchair onto the pavement so that the weight is divided

across all four wheels. Ensure that the wheelchair does not roll back-

wards.

Off a kerb

Follow the procedure above but in reverse order (steps 4, 3, 2 and 1)

to move off the kerb.

Kerbs - Alternative method

This method is generally used by experienced assistants who are

stronger than average. The method can also be used when the kerb or

step is low and only constitutes a minimal obstacle.

The assistant steps backwards onto the pavement and pulls the wheel-

chair up onto the pavement. It is important for the assistant to use

their body correctly to prevent injury. Tip the wheelchair backwards

and roll the chair over the kerb onto the pavement. Take particular

care if the kerb is wet or slippery.

Escalators

Do not use escalators with a wheelchair. Find out if there is a lift

nearby.

Stairs

We advise you to avoid going up/down stairs in your wheelchair where

possible and instead choose an alternative route.

We recommend that you receive help from two assistants to get up

and down stairs. One assistant goes in front and holds the wheelchair’s

frame and the other goes behind and holds the push handles. Fold the

anti-tip devices upwards. Balance the wheelchair on the drive wheels

until the balance point is found. Then roll the chair step by step down

the stairs by letting the wheelchair roll over the edge of each step. It is

important that assistants remember not to hold detachable arm rests

or leg rests. Assistants much also remember to lift correctly, using

their legs and keeping their back as straight as possible.

Summary of Contents for Rea Spirea4 NG

Page 1: ...4 R pirea User Manual English...

Page 39: ...39...