10

Alarm Function

The red Alarm LED will flash and an audible alert will

sound to indicate the control unit or mattress pressure

has failed. The LED will remain illuminated until

appropriate pressure is restored. The audible alarm

can be silenced by pressing the Alarm Mute button.

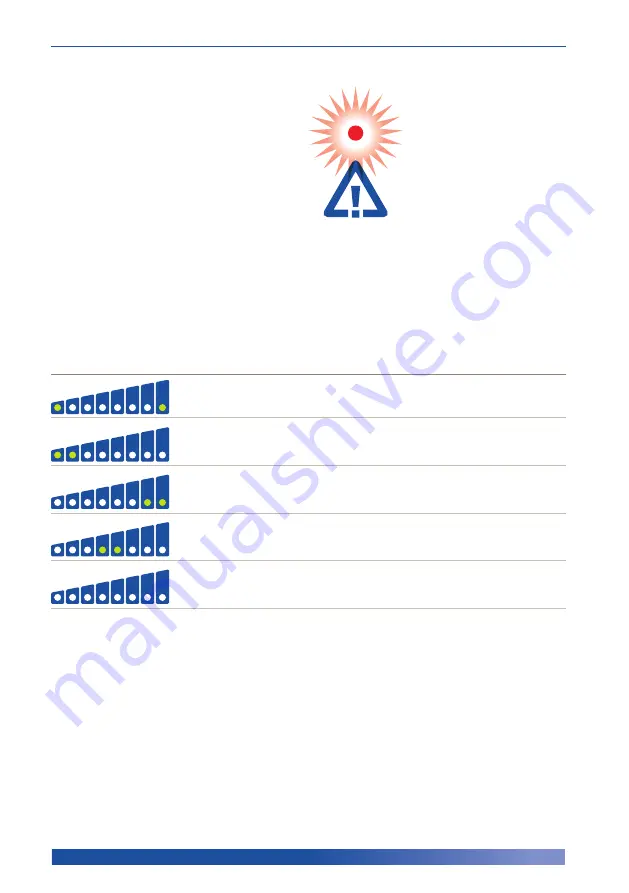

The system has five different alarm signals

which can be identified by five different Pressure

Setting illumination sequences. The signals and

corresponding Pressure Setting LED displays are

illustrated below

Operation

Display

Alarm Signal

Initial Failure

Mattress has failed to reach minimum operational

pressure within 50 minutes

Low Pressure

Pressure has fallen 5mmHg or more below the setting

minimum

High Pressure

Pressure has exceeded the maximum setting by

10mmHg or more

Alternating

Mattress has failed to commence alternation

Mode failure

AC power failure

No pressure output due to mains power failure

If the alarm activates and the system fails to inflate or

loses pressure, please refer to the

Troubleshooting

section on the following pages.