SECTION 3—SAFETY INSPECTION/TROUBLESHOOTING

32

Motor Brush Inspection and/or Replacement

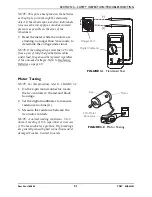

NOTE: For this procedure, refer to FIGURE 3.3 on page 33.

NOTE: There is one contact brush under each brush cap on the motor housing. There are four

motor brushes on a 4 pole motor and two motor brushes on a 2 pole motor.

NOTE: If the brush caps are hard to remove they are either overtightened or the motor has become

very hot. Allow 30 minutes for motors to cool. If brush caps still cannot be removed, it is

recommended that the motor be sent to Invacare Technical Services for inspection/repair at the

address located on the back cover of this manual.

1. Turn the power off.

2. Disengage the motors.

3. Locate a brush cap on the motor. See Detail “A” in FIGURE 3.3.

4. Remove the brush cap with a flat head screwdriver.

5. Pull the motor brush partially out of the brush holder. See Detail “B” in FIGURE 3.3.

NOTE: If not installing a new motor brush, it is very important to note which way the existing

motor brush comes out of the motor. The existing motor brush MUST be placed into the motor

exactly the same way to ensure good contact with the commutator.

6. Place a temporary mark on the motor casting and on the top of the motor brush to

indicate the orientation.

7. Remove the motor brush from the brush holder.

8. Inspect the motor brush thoroughly for excessive wear or chips in the brush and any

discoloration in the shunt wire.

9. Perform one of the following:

• If motor brush is in good condition, (i.e., the end of the brushes are smooth and

shiny, the spring is not damaged or discolored, and shunt wire is not discolored)

perform the following:

i. Install existing motor brush into brush holder exactly the same way it was

pulled out using the marks as reference points.

ii. Install motor brush cap.

NOTE: Tighten and loosen motor brush cap a couple times to ensure proper seating of the

motor brush.

• If motor brush is in bad condition (brush is worn or damaged) replace immediately

by performing the following:

i. Install new motor brush into brush holder.

ii. Install motor brush cap.

NOTE: This process, also called Brush Burn-in or Finger Printing Process, is necessary to

seat the brush to the commutator plates inside the motor for optimum performance of the

motor.