33

TECHNICAL DATA

33

iV-Light ventilation unit | Installation instructions

iV-Light ventilation unit, manually controlled:

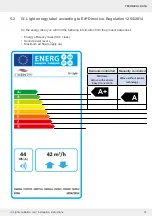

iV-Light product data sheet according to

EU Ordinance 1254/2014 dated 11 July 2014

Pt

Description

Values

a

Supplier

inVENTer GmbH

b

Model identifier

iV-Light

c

SEC class / Specific Energy

Consumption (SEC) [kWh/(m²a)]

Cold

-78.012

Average

A

-36.847

Warm

-13.265

d

Ventilation type

BVU

e

Type of drive

2

f

Type of heat recovery system

Regenerative

g

Degree of temperature change ƞ

t

[%]

84

h

Maximum air flow rate [m³/h]

42

i

Electrical input power (incl. control) [W]

6

j

Sound power level L

wa

[dB (A)]

44

k

Reference air flow [m³/h]

29.4

l

Reference pressure difference [Pa]

0

m

SEL [W/m³/h]

0.18

n

Control factor

1

o

Internal and external transfer [%]

n. a.

p

Mixing quota [%]

n. a.

q

Position and description of the indicator for filter change

Control unit

r

Instructions regarding controllable supply and extract air

grilles on the façade (unidirectional ventilation devices

only)

None

s

Internet address

t

Sensitivity to pressure changes [%]

28.5

u

Airtightness between interior and exterior [m

3

/h]

1.2

v

Annual power consumption [kWh/(m²a)]

2.48

w

Annual savings

Heating energy [kWh/(m²a)]

Cold

84.69

Average

43.29

Warm

19.58

Summary of Contents for 1001-0200

Page 1: ...www inventer de Installation instructions iV Light ...

Page 37: ...37 WARRANTY AND GUARANTEE 37 iV Light ventilation unit Installation instructions NOTES ...

Page 38: ...38 WARRANTY AND GUARANTEE 38 iV Light ventilation unit Installation instructions NOTES ...

Page 39: ...39 WARRANTY AND GUARANTEE 39 iV Light ventilation unit Installation instructions NOTES ...