Goodrive350 IP55 High-ingress Protection Series VFD

Safety Precautions

-2-

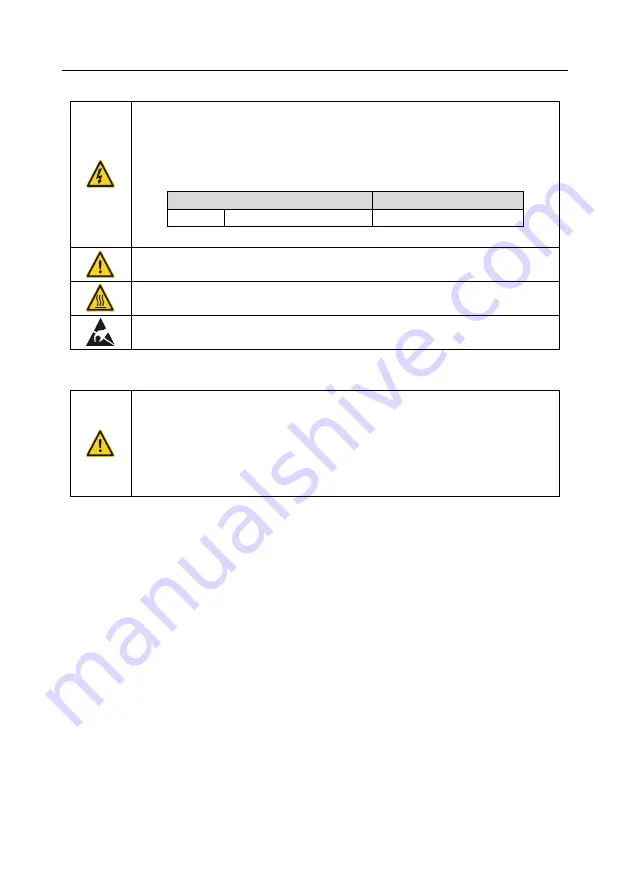

1.4 Safety guidelines

Only trained and qualified electricians are allowed to carry out related operations.

Do not perform wiring, inspection or component replacement when power supply

is applied. Ensure all the input power supplies are disconnected before wiring

and inspection, and wait for at least the time designated on the VFD or until the

DC bus voltage is less than 36V. The minimum waiting time is listed in the table

below.

VFD model

Minimum waiting time

380V

004G/5R5P

–110G

5 min

Do not refit the VFD unless authorized; otherwise, fire, electric shock or other

injuries may occur.

The base of the radiator may become hot during running. Do not touch to avoid

hurt.

The electrical parts and components inside the VFD are electrostatic. Take

measures to prevent electrostatic discharge during related operation.

1.4.1 Delivery and installation

Install the VFD on fire-retardant material and keep the VFD away from

combustible materials.

Connect the optional brake parts (brake resistors, brake units or feedback units)

according to the wiring diagram.

Do not operate on a damaged or incomplete VFD.

Do not touch the VFD with wet items or body parts; otherwise, electric shock may

occur.

Note:

Select appropriate tools for delivery and installation to ensure a safe and proper running of

the VFD and avoid physical injury or death. To ensure physical safety, the installation staff

should take mechanical protective measures like wearing exposure shoes and working

uniforms.

Ensure to avoid physical shock or vibration during delivery and installation;

Do not carry the VFD by its front cover only as the cover may fall off;

Installation site should be away from children and other public places;

The VFD should be used in proper environment (see section 4.2.1 "Installation

environment" for details);

Prevent the screws, cables and other conductive parts from falling into the VFD;

As leakage current of the VFD during running may exceed 3.5mA, ground properly and

ensure the grounding resistance is less than 10

Ω. The conductivity of PE grounding

conductor is the same with that of the phase conductor. For models higher than 30 kW, the

cross sectional area of the PE grounding conductor can be slightly less than the

recommended area.

R, S and T are the power input terminals, and U, V and W are output motor terminals.

Connect the input power cables and motor cables properly; otherwise, damage to the VFD

may occur.