Chapter 4 Compressor Safety

37

AIR/OIL COALESCER

The coalescer is self-contained within a spin-on housing and is independent of the sump. When

air is demanded at the service line, it passes through the coalescer which efficiently provides the

final stage of oil separation.

OIL RETURN LINE

The oil that is removed by the coalescer accumulates at the bottom of the can and is returned

through an oil return line leading to the compressor. The oil return line is 1/4" and goes to the

elbow hose fitting which is located at the compressor.

MINIMUM PRESSURE VALVE

The minimum pressure valve is located at the outlet of the coalescer head and serves to

maintain a minimum discharge pressure of 65 PSIG in operation, which is required to assure

adequate compressor lubrication pressure.

OIL FILTER

The compressor oil filter is the full-flow replaceable element type. It has a built in safety bypass.

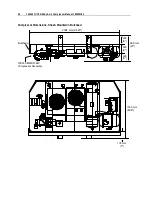

COMPRESSOR COOLING SYSTEM

The compressor cooling system consists of a combination aftercooler and oil cooler remote

mounted on the common frame. Compressor oil temperature is controlled by a thermal valve

located downstream of the oil filter. This valve maintains compressor oil temperature at 185° F.

Compressed air is cooled in the small section of the combo cooler and sent directly to the 22-

gallon air tank.

INSTRUMENTATION

The IMT hydraulic drive compressor unit incorporates a gauge panel that monitors temperature

and hours of operation.

HOURMETER

The hourmeter records the total number of operating hours. It serves as a guide in following the

recommended inspection and maintenance schedule. The hourmeter will only run when there is

pressure in the system.

COMPRESSOR DISCHARGE AIR/OIL TEMPERATURE SWITCH GAUGE

This switch/gauge indicated compressor air discharge temperature. The switch/gauge ensures

safety shutdown in case of excessive operating temperatures, preventing compressor damage.