38

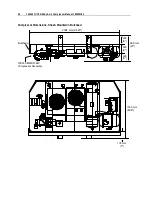

14K160TH OTR Body & Air Compressor Manual # 99903184

ELECTRICAL AND SAFETY SYSTEM

The IMT compressor includes the following in the standard electrical system:

Gauge panel with a temperature switch gauge and high temperature hydraulic cooling light.

Hydraulic oil cooler / fan assembly with temperature sender and relay.

Compressor aftercooler/oil cooler fan assembly with relay.

N.O. hourmeter pressure switch.

N.C blowdown pressure switch.

12 V DC N.O. hydraulic solenoid and relay.

12 V DC diode protected power feed for engine speed control activation.

AUTOMATIC BLOW DOWN VALVE

There is one blow down valve in the compressor system. It is located at the downstream side of

the coalescer head and will automatically bleed the sump to zero pressure when the compressor

is disengaged. The blow down time interval is typically 30 to 60 seconds.

CONTROL SYSTEM

The prime component of the compressor control system is the compressor inlet valve. The

control system is designed to match air supply to air demand and to prevent excessive

discharge pressure when compressor is at idle. Control of air delivery is accomplished by the

inlet valve regulation and modulation as directed by the discharge pressure regulator.

DISCHARGE PRESSURE REGULATOR VALVE

This valve, located on the coalescer head, is used to set the desired discharge pressure within

the operating pressure range. Turning the regulator screw clockwise increases the working

pressure; a counterclockwise movement of the screw reduces the working pressure. This

system has a maximum operating pressure of 150 psi.

NOTE

The operating pressure range for most air tools is between 90 and 100 psi. Operating above

the tools' recommended pressure will decrease the life of the tool. Higher operating pressure

can also overtorque nuts and bolts, causing fastener and mating part fatigue. Strictly adhere

to tool operating pressures and torque standards set forth by the tool manufacturer and the

specifications of the equipment that work is being performed on.

INLET VALVE

The compressor inlet valve is a piston operated disc valve that regulates the inlet opening to

control capacity and serves as a check valve at shutdown.