Chapter 6 Compressor Operation

57

Compressor Operating Conditions

If possible, operate the compressor with the truck as close to level as possible. The compressor

will operate on a 15° tilt from side to side and end to end without adverse problems. Fluid carry

over and/or oil starvation may occur if operated at a tilt beyond 15°. Operation in ambient

temperatures above 100° F may result in high temperature shutdown.

NOTE

If the compressor is being used to power sandblasting equipment or an air storage tank, use a

check valve directly after the minimum pressure orifice to prevent backflow into the sump.

This check valve should have a maximum pressure drop rating of 2 PSIG (13.78 kPa)

operating and a capacity rating equal to the compressor.

NOTE

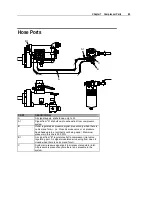

When a hose reel is not used, the compressor service valve should be relocated to the hose reel

inlet, or to a customer-supplied air connection port. Typical plumbing from a minimum pressure

orifice should flow in the following order:

1

Minimum pressure orifice

2

Check valve

3

Air tank (when used)

4

Service valve

5

Moisture trap/ gauge / oiler combination (when used)

6

Hose reel (when used)