DA440PBU: 99900403:

2-2

19990119

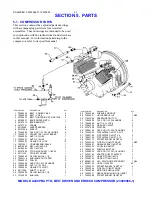

2-3. UNDER-DECK COMPRESSOR

INSTALLATION

Due to the large variety of carrier vehicles, the

instructions in this paragraph should be used as a

guide only.

1.

Position the compressor below the bed of the

truck in the desired location. The location selected

should provide adequate ventilation while at the

same time affording protection against road hazards

and dirt.

2.

Lift the compressor base into position. Check

for belt clearance and approximate drive shaft

length.

3.

Using the base as a template, drill two holes 17/

32" diameter, and two holes on the other side of the

frame 21/32" diameter.

4.

Bolt the compressor base to the frame of the

truck using the 1/2" and 5/8" hardware.

5.

Using the appropriate driveshaft with knuckles

in place, measure the exact length required, cut off

excess shaft and weld in place (1/4" weld all

around).

6.

Install the driveshaft to the PTO and the

compressor, tighten the lock bolts and tie-wire in

place.

7.

Tighten all bolts.

8.

Connect the 3/4" air hose from the compressor

to the air tank.

9.

Install the engine speed control and connect the

hoses from compressor to speed control.

Summary of Contents for Diamond Air 80 PTO

Page 6: ...DA440PBU 99900403 1 2 19940729 NOTES...

Page 10: ...DA440PBU 99900403 3 2 19950719 NOTES...

Page 12: ...DA440PBU 4 2 99900403 19940729...

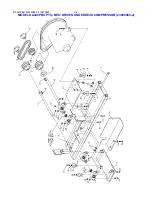

Page 19: ...DA440PBU 5 7 DA440PBU COMPRESSOR CLOCKWISE TRANSMISSION 23000952 2 23000952 02 19970907...

Page 20: ...DA440PBU 5 8 19990119...

Page 22: ...DA440PBU 99900403 6 2 19940729 FIGURE F 2 TIRE LOAD AND INFLATION PRESSURES...

Page 23: ...DA440PBU 99900403 6 3...