DA440PBU: 99900403:

3-1

19950719

SECTION 3. OPERATION

3-1. OPERATION

This section deals with the proper methods of

system operation and shutdown. These procedures

should be followed to prevent damage and ensure

efficient operation.

Start the compressor as follows:

1. Ensure the PTO is disengaged and the receiver

drain cock is open.

2. Start the truck engine and allow it to idle until it

reaches the proper operating temperature (refer to

the Owners Manual).

3. Depress the clutch, engage the PTO and

carefully release the clutch pedal.

4. Activate the engine speed control by closing the

receiver drain cock. The compressor is now

operating and supplying working air.

NOTE

WHEN STARTING THE COMPRESSOR, THE RPM’S

WILL AUTOMATICALLY INCREASE DUE TO LOW

VOLUME OF AIR IN THE SYSTEM

CAUTION

1000 RPM MAX.

Operating this unit in excess of 1000 RPM, measured at

the compressor flywheel, will void your warranty. Engine

RPM may be different.

3-2. SYSTEM SHUTDOWN

System shutdown is accomplished as follows:

1. Allow the compressor to build to maximum

pressure and the truck engine will automatically idle

down.

2. Place the compressor control valve in the open

(off) position.

3. Depress the clutch pedal and disengage the PTO.

4. Open the receiver drain cock and discharge the

air in the receiver.

WARNING

FEDERAL LAW PROHIBITS DRIVING THE CARRIER

VEHICLE ON PUBLIC ROADS WITH THE RECEIVER

FILLED WITH COMPRESSED AIR. ALWAYS DRAIN THE

RECEIVER BEFORE MOVING THE VEHICLE.

Summary of Contents for Diamond Air 80 PTO

Page 6: ...DA440PBU 99900403 1 2 19940729 NOTES...

Page 10: ...DA440PBU 99900403 3 2 19950719 NOTES...

Page 12: ...DA440PBU 4 2 99900403 19940729...

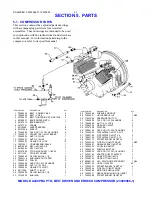

Page 19: ...DA440PBU 5 7 DA440PBU COMPRESSOR CLOCKWISE TRANSMISSION 23000952 2 23000952 02 19970907...

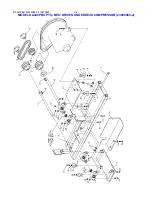

Page 20: ...DA440PBU 5 8 19990119...

Page 22: ...DA440PBU 99900403 6 2 19940729 FIGURE F 2 TIRE LOAD AND INFLATION PRESSURES...

Page 23: ...DA440PBU 99900403 6 3...