ENGLISH

18

10.

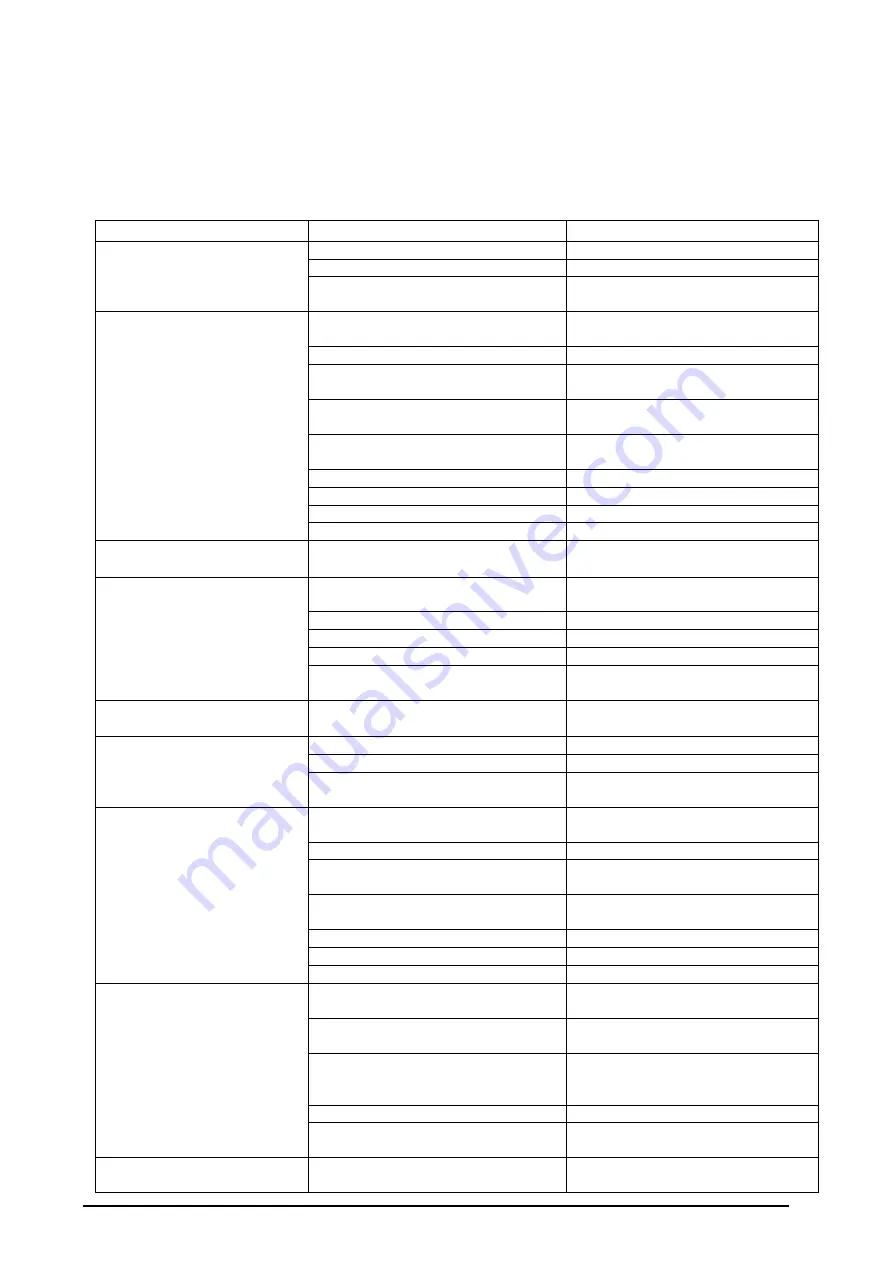

TROUBLESHOOTING AND ERROR CODES

10.1. How to resolve possible problems

Possible problems affecting the whole machine.

PROBLEM

CAUSE

REMEDY

The battery is disconnected

Connect the battery to the machine

The battery is flat.

Recharge the battery

The machine does not

function

Logic board power supply fuse

blown.

Replace fuse

The brush button has not been

pressed

Press the brush button

The brush lever has not been pulled

Pull the brush lever

The brush motor fuse has blown

Check and remove the causes of

the blown fuse, then replace

Logic board power supply fuse

blown.

Replace fuse

The motor thermal cutout has

tripped (battery version)

Wait for the motor to cool down

Brush motor contactor broken

Replace contactor

The batteries are flat

Recharge the batteries

Motor malfunction

Replace the motor

The brushes do not turn

Control board fault

Replace control board

The machine does not

clean evenly

The brushes or abrasive disks are

worn

Replace

The tap upstream of the head is

closed

Open the tap

Solenoid valve fault

Replace the solenoid valve

The detergent tank is empty

Fill the detergent tank.

Detergent tank filter dirty

Detergent tank filter cleaned

No detergent is delivered

The hose delivering the detergent to

the brush is blocked

Remove the obstruction to open the

hose

The detergent flow does

not stop

Solenoid valve fault

Replace the solenoid valve

Solenoid valve fault

Replace the solenoid valve

Detergent tank filter dirty

Detergent tank filter cleaned

The flow of detergent is

interrupted

during

operation

The hose delivering the detergent to

the brush is blocked

Remove the obstruction to open the

hose

The suction switch has not been

turned on

Turn the suction switch on

Motor malfunction

Replace the motor

The brush motor fuse has blown

Check and remove the causes of

the blown fuse, then replace

Logic board power supply fuse

blown.

Replace fuse

Suction motor contactor broken

Replace contactor

The batteries are flat

Recharge the batteries

The suction motor does

not start.

Control board fault

Replace control board

The edge of the rubber blades in

contact with the floor is worn

Replace the rubber blade

The squeegee or hose is blocked or

damaged

Remove the obstruction and repair

the damage

The float switch has tripped (dirty

water tank full), is blocked with dirt

or is faulty

Empty the dirty water tank or repair

the float

The suction hose is blocked

Unblock the hose

The squeegee does not

clean

or

suction

is

ineffective

The hose is not connected to the

squeegee or is damaged

Connect or repair the hose

The battery does not last The battery poles and terminals are

dirty and oxidised

Clean and grease the poles and

terminals, charge the battery

Summary of Contents for G25B

Page 1: ...ENGLISH ...