English

- 16 -

hard water (> 15°TH), carry out maintenance more frequently.

The boiler’s scaling should be made only by an authorized

assistence service.

This operation requires the machine to be located in the assi-

stence service.

For maintenance and/or repairs, use only original spare

parts which offer the greatest characteristics of quality and

reliability. Failure to use original spare parts absolves the

manufacturer from all liability and transfers it to the person

carrying out the operation.

STORAGE

If the appliance is not used for long periods, unplug it from the

mains socket, empty and wash the waste drum and clean the

boiler. Protect parts which might be damaged by dust. Empty

the water and cleaning solution tanks via the relative drainage

bungs. Rinse the cleaning product delivery circuit using clean

water.

When used again, check there are no cracks or cuts in the

vacuum and solution/steam emission tubes and attachments.

SCRAPPING

If you decide to stop using the steam generator, you should

render it inoperative by removing the electric power cable. Parts

which might constitute a danger, especially to children playing

with the appliance, should be made harmless.

This product is classified as WEEE type special waste and is

covered by the requisites of the new environmental protection

regulations. It must be disposed of separately from ordinary

waste in compliance with current legislation and standards.

Do not use the components removed as spare parts.

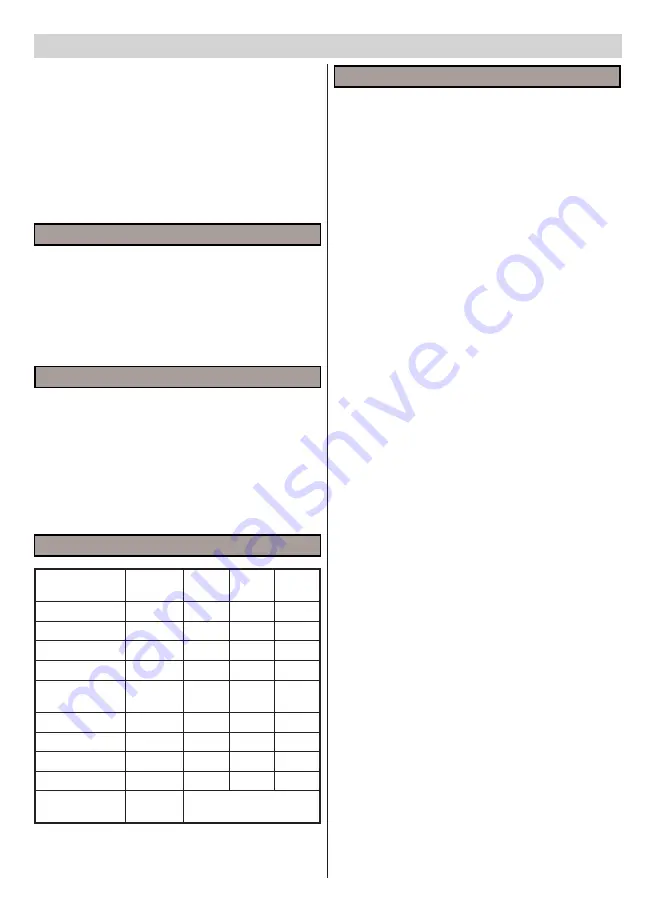

TECHNICAL CHARACTERISTICS

Mod.

SG

5008

SG

5010

SG

5014

Boiler volume

l

4

4

5

Oper. pressure

bar

5,0

5,0

7,0

Steam temp.

°C

160

160

160

Abs. power. boil. W

2900

3660

7100

Max. all. imped-

ance

Ohm

0,35

0,35

Solut. tank

l

6

6

6

Water tank

l

6

6

6

Del. pump

W

60+60

60+60

60x3

Weight

Kg

35

35

36

Noise level

Lp dB (A)

Lw dB (A)

72 (Kp 2)

81 (Kw 2)

TROUBLESHOOTING

Problem

The appliance does not work.

Cause

No voltage.

Faulty cable or mains switch.

Remedy

Make sure there is voltage.

Contact the service centre.

Problem

Water comes out of head (air output)

Cause

Collection drum too full.

Remedy

Empty drum and check float. Clean if necessary.

Problem

No chemical product delivered

Cause

Solution tank empty. (Intermittent beep)

Attachments dirty or clogged.

Detergent intake circuit clogged.

Pump does not suck.

Damaged delivery pump.

Remedy

Fill the solution tank with cleaning product.

Clean attachments.

See paragraph on filling the cleaning product suction circuit.

Contact the service centre.

Problem

Considerable drop in suction power.

Cause

Clogged or broken tubes, hose or attachments.

Drum too full.

Head not perfectly adhering.

Remedy

Clean or replace tubes or accessories.

Empty drum.

Check adherence of head to drum and check that hooks fit

correctly.

Problem

Engine turns quickly (high pitched noise).

Cause

Clogged tubes or accessories

Drum too full.

Remedy

Clean tubes or accessories.

Empty drum.

Summary of Contents for S 5008M

Page 3: ... 3 Fig 1 Fig 3 Fig 5 Fig 2 Fig 4 Fig 6 ...

Page 4: ... 4 Fig 7 Fig 9 Fig 8 Fig 10 Fig 11 Fig 12 I H G ...

Page 5: ... 5 Fig 13 Fig 14 ...

Page 42: ...Note Notes ...

Page 43: ...Note Notes ...