Better Packages

Section 4

Maintenance

24

There is very little maintenance required to keep your tape dispenser working in top condition. However,

the maintenance that is required is important to perform.

Maintenance is basically:

• Cleaning the water tank, bottle, and brushes

• Keeping the shear blade clean

• Keeping the machine clear of tape jams

• Keeping the blade oiler moist

These are outlined in the following pages.

WASHING THE TANK, BRUSHES, AND BOTTLE

Water Brushes: Glue from the tape may accumulate and reduce the effectiveness of the moistening

system. Wash brushes weekly with mild soap.

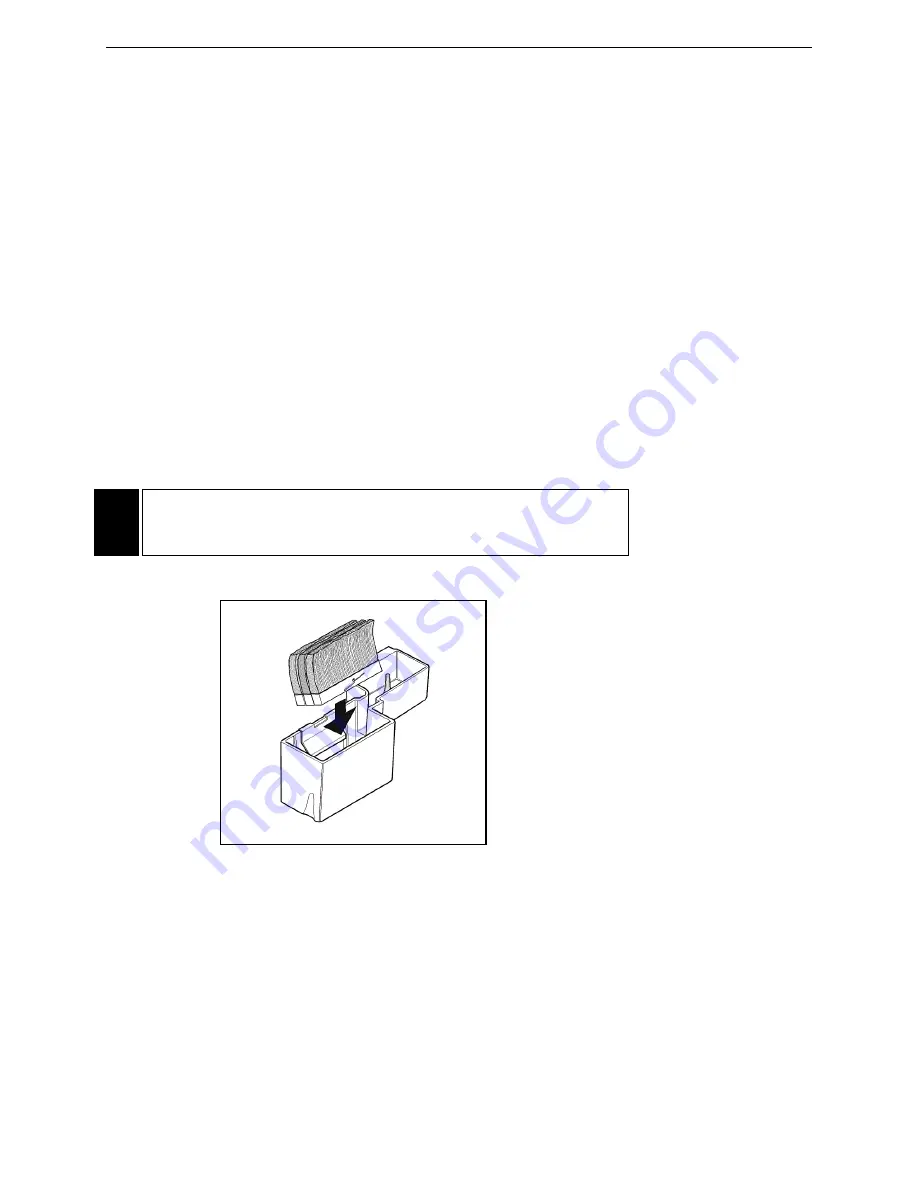

To remove any old dried adhesive, you will need to tilt the brushes to clear the retaining bracket. Be sure

to replace the brushes in the tank correctly.

See Figure 17

. Facing the brushes in the wrong direction can

result in poor moistening and tape jamming.

The brush tips are cut at an angle and in 3 unique lengths.

They are designed to be used in one direction only.

FIGURE 17 - Inserting Brushes into the Tank

WARNING: Never cut the ends of the brush tips to remove dried

glue ... the brush will be too short and will not work properly.

!