15

Before Each Use – Inspection/Maintenance

5. Hydraulic System Check the hydraulic system carefully:

1.

Visually inspect all hoses, tubing, clamps/fittings, pump, and cylinder for cracks, fraying,

kinks, or other damage.

2.

Check all components for oily residue, which may indicate a leak.

Do NOT operate the log splitter if there is any indication of damage or oily residue. Small leaks

in hydraulic lines can cause severe injuries and can also be an indication of catastrophic failure

in the near future. The life of hydraulic hoses may be from a few months to a few years,

depending on use and storage patterns.

WARNING

:

High fluid pressures and temperatures are developed in hydraulic log

splitters. Hydraulic fluid escaping through a pin-hole sized opening can burn or

puncture skin, resulting in wounds that could cause blood poisoning, infection,

disability, gangrene, amputation, or death. Therefore, the following instructions should

be heeded at all times when inspecting or servicing the hydraulic components of the log

splitter:

Stop the engine, disconnect the spark plug, and move all control valve handles back

and forth to relieve pressure before changing or adjusting hydraulic system

components such as hoses, tubing, fittings, or other components.

NEVER check for leaks with your hand. Leaks can be located by holding a piece of

cardboard or wood (at least two feet long) with your hand at one end and passing the

other end near the suspected area (wear eye protection). Look for discoloration of the

cardboard or wood.

NEVER adjust the pressure setting of the pump or valve.

If injured by escaping fluid, no matter how small the wound, see a doctor at once. A

typical injection injury may be a small puncture wound that does not look serious.

However, severe infection or reaction can result if proper medical treatment is not

administered immediately by a doctor familiar with injection injuries.

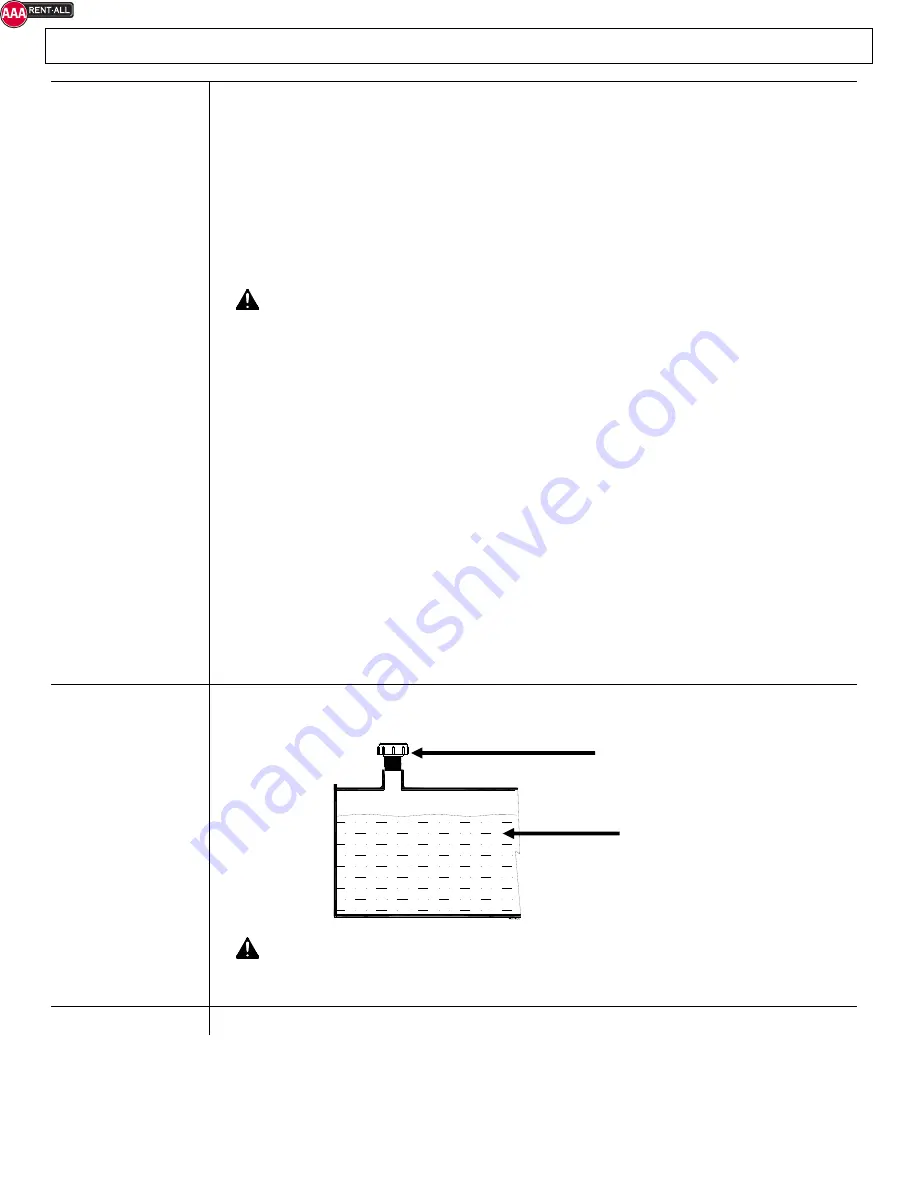

6. Hydraulic Oil

Level

Check the hydraulic oil level.

Fill as needed – The hydraulic oil level should be 1” from the

top of the hydraulic tank with the cylinder retracted.

WARNING:

NEVER remove the hydraulic oil fill cap when the engine is running or

hot. Hot oil can escape causing severe burns. Allow log splitter to cool completely

before removing hydraulic oil fill cap.

7. Engine

Inspect and perform engine maintenance as directed in the engine manual.

Oil Fill Cap

Hydraulic Oil

*Call AAA Rent-All at 225-291-1356 for assistance ordering parts*