FLAIL MOWER – FM Series

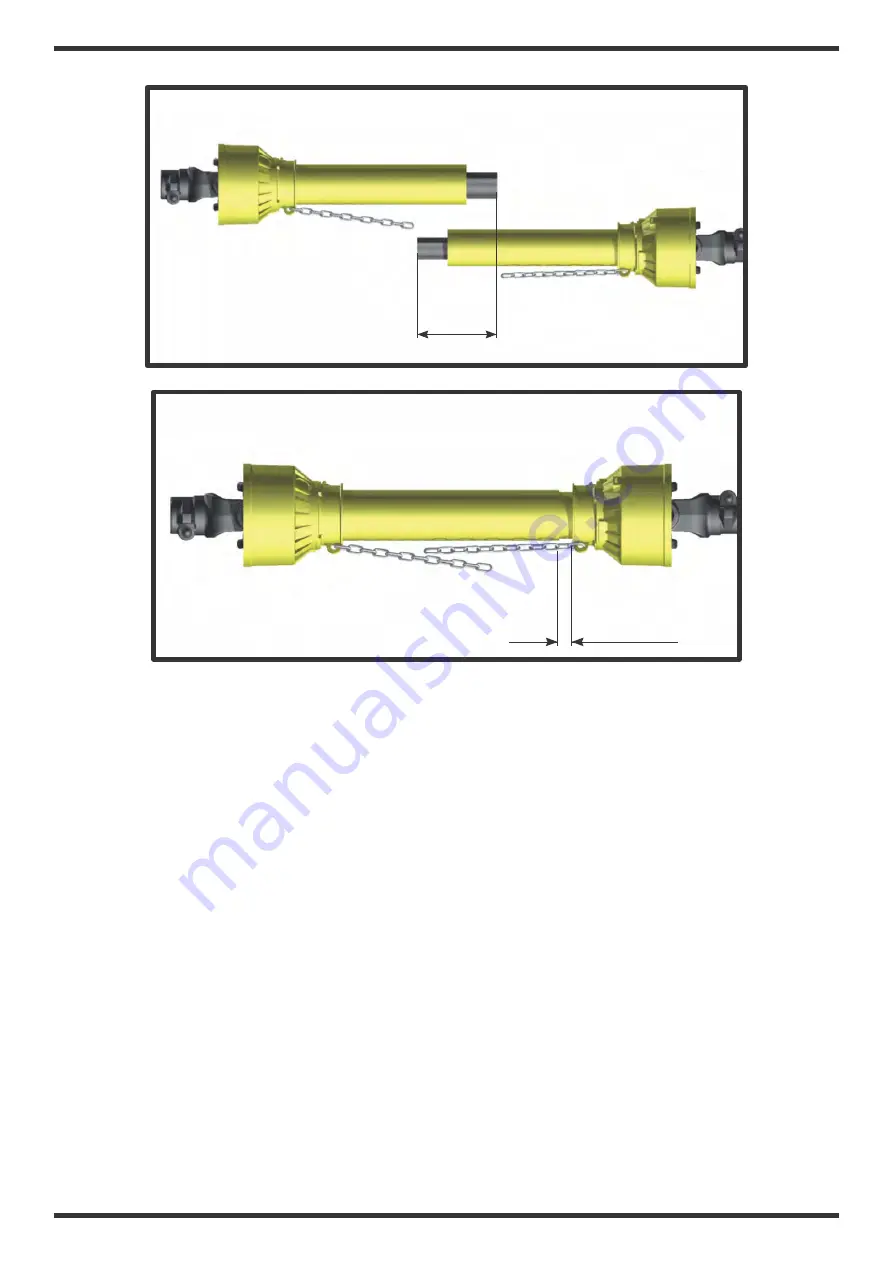

max extenDeD position

15 cm

max compResseD position

2 cm

A driveshaft too long may cause structural damages to the tractor and machine. If the driveshaft is too

long, it may be adapted by removing it and shortening the tubes according to the instructions provided by

the Manufacturer in its use and maintenance manual.

A driveshaft too short can cause disengage of the tubes during operation, with severe hazard for the ope-

rator and structural damage to the tractor and machine. If the driveshaft is too short, it must be replaced

with a longer one. In this case contact the Manufacturer or your Dealer.

IMPORTANT

• before operating the flail mower the first time, make sure that the driveshaft is lubricated in

accordance with how indicated in the instruction booklet;

• before operating the flail mower the first time, and after long periods of inactivity, make sure that the

driveline clutch has run a short “run in” in accordance with what indicated in the instruction manual of the

Manufac- turer, removing the possible oxidation of the components that may compromise the correct

slipping during the usage (see also section “Maintenance”);

• always engage the tractor PTO at low rpm to minimize the effect of the peak torque on the driveline and

the machine.

4.3. TRACTOR-FLAIL MOWER STABILITY

The weight of the machine modifies the stability of the system tractor-flail mower, resulting in loss of

steering

control and braking.

The front axle of the tractor should always loaded with at least 20% of the overall weight of the system

tractor-flail mower.

Summary of Contents for FMH Series

Page 43: ......

Page 45: ......

Page 46: ...FLAIL MOWER FMH Series NOTES ...

Page 47: ...FLAIL MOWER FMH Series NOTES ...