© 2019 IRONRIDGE, INC. VERSION 1.8

BX SYSTEM INSTALLATION MANUAL - 4

OVERVIEW

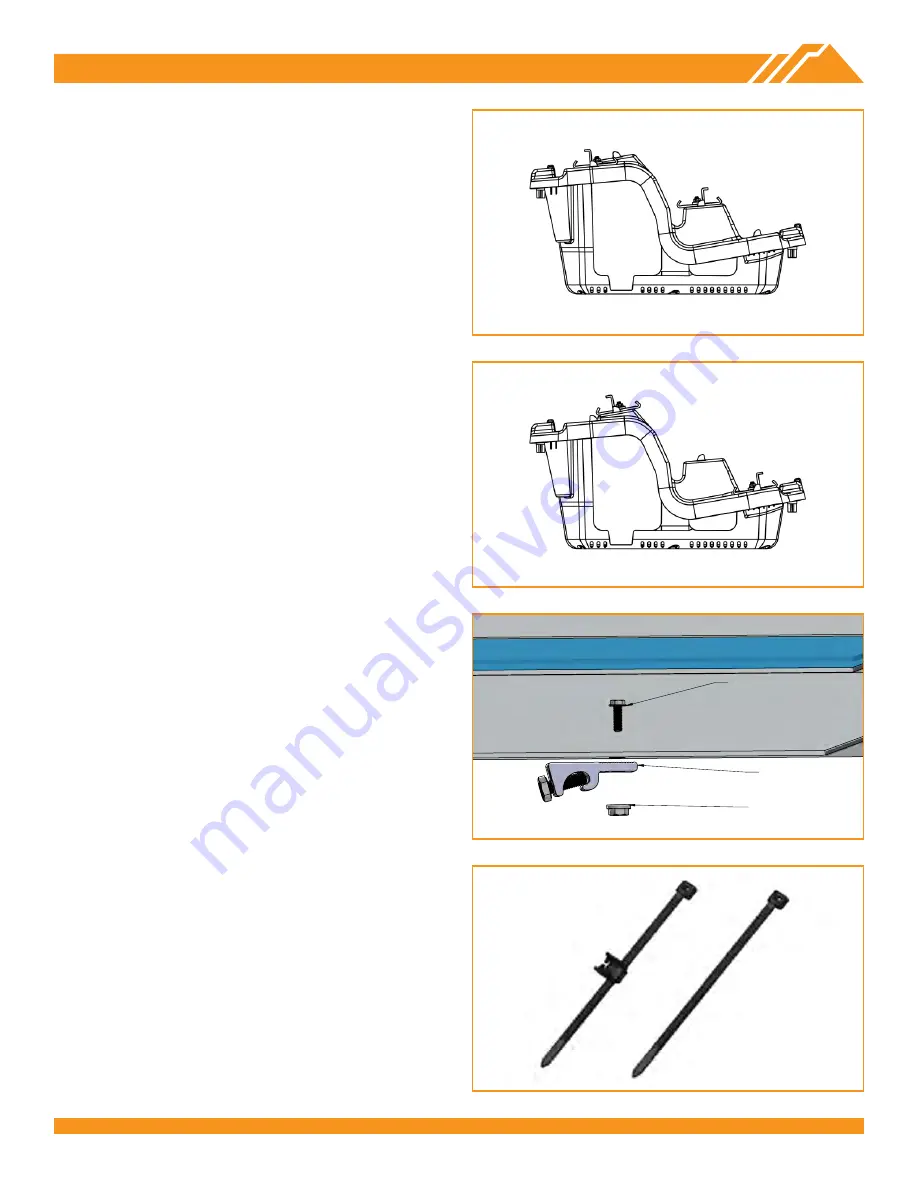

BX CHASSIS (5° & 10°)

BX Chassis is designed to clamp PV modules and secure

them in place. Reference tabs are integrated to aid

with aligning modules according to system layout. The

Chassis is available in two SKUs: 5 and 10 degree tilt

configurations. The Chassis is designed to accommodate

4 full size (16” x 8” x 4”) or 8 half-size concrete ballast

blocks (16” x 8” x 2”) nominal dimensions.

Concrete ballast block must meet the following

requirements:

• Manufactured per ASTM C 1491 (Standard

specification for concrete pavers)

• Manufactured to resist freeze-thaw as required per

local conditions

• Weight: 14-17 lbs +/- 2 lbs for half size and 28-34

lbs +/- 2 lbs for full size

• Compressive Strength requirement: 3000 PSI min

MODULE CLAMPING

Top Clamps are module frame height specific and

accommodate most common module sizes: 30mm, 32mm,

33mm, 35mm, 38mm, 40mm, 46mm.

ARRAY GROUNDING

Only one PV Module Grounding Lug is required per

continuous array, regardless of array size. Use the

IronRidge PV Module Grounding Lug (PV-LUG-01-A1).

Alternately, the following grounding lugs have been tested

or evaluated for use with the BX system:

• Ilsco GBL-4DBT

• Amphenol HGLUI

• Burndy CL501TN, BGBS4

MLPE DEVICES (OPTIONAL)

The following MLPE module mounting brackets have been

tested or evaluated for use with the BX system:

• EcoFasten Frame MLPE Mount

• QMPV Accessory Frame Bracket

➢

Refer to respective installation instructions of MLPE module

mounting brackets.

WIRE MANAGEMENT

Optional Edge Clips and wire ties can be used to aid with

wire management.

FLANGE NUT

GROUNDING LUG

BOLT